Abstract

Especially in high speed milling of aluminum alloys in the aviation industry, chamfered milling tools have proven themselves. Due to the chamfer, an extended contact between the tool and the workpiece at the flank face is evoked, which leads to additional process damping forces opposed to tool vibrations. Hence, the cutting process shows improved stability characteristics. This article presents an approach for the identification and modeling of these process damping effects in transient milling simulations. For this purpose, a simulation- and experiment-based procedure for the identification of required simulation parameters depending on the tool chamfer geometry is introduced and evaluated. Finally, the identified parameters are used for transient simulations of milling processes with extended stability due to the tool chamfer. The suitability of the proposed identification method and simulation model for milling with process damping is finally proved by a comparison between simulations and experiments.

Similar content being viewed by others

References

Malekian M, Park SS, Jun MB (2009) Modeling of dynamic micro-milling cutting forces. Int J Mach Tool Manuf 49:586–598

Rahnama R, Sajjadi M, Park SS (2009) Chatter suppression in micro end milling with process damping. J Mater Process Technol 209:5766–5776

Budak E, Tunc L (2010) Identification and modeling of process damping in turning and milling using a new approach. CIRP Ann-Manuf Technol 59:403–408

Ahmadi K, Ismail F (2011) Analytical stability lobes including nonlinear process damping effect on machining chatter. Int J Mach Tool Manuf 51:296–308

Tyler CT, Schmitz TL (2013) Analytical process damping stability prediction. J Manuf Process 15:69–76

Denkena B, Bickel W, Sellmeier V (2012) Flank milling of compliant workpieces with chamfered tool. Prod Eng Res Dev 6:403–412

Sellmeier V (2012) Einfluss der Werkzeuggestalt auf die dynamische Stabilität des Fräsprozesses. Dr.-Ing. Diss., Leibniz Universität Hannover

Denkena B, Jivishov V, Clausen M (2003) Deviation analysis of FEM based cutting simulation. In: 6th ESAFORM conference on material forming, Salerno, Italy

Biermann D, Hess S, Tiffe M, Wagner T, Zabel A (2012) Statistically assisted identification of the material and friction parameters for modeling metal cutting processes using the fea. International conference on thermo-mechanically graded materials, 1, pp 25–30

Maurel-Pantel A, Fontaine M, Thibaud S, Gelin JC (2012) 3D FEM simulations of shoulder milling operations on a 304L stainless steel. Simul Model Pract Theory 22:13–27

Böß V, Ammermann C, Niederwestberg D, Denkena B (2012) Contact zone analysis based on multidexel workpiece model and detailed tool geometry representation. In: 3rd CIRP conference on process machine interactions. Procedia CIRP 4:40–44

Weinert K, Guntermann G, Stautner M (2001) Effiziente Simulation der 5-Achsen-Simultan Fräsbearbeitung. 3D-Erfahrungsforum Werkzeug- und Formenbau. Begleitband 1:197–205

Altintas Y (2000) Manufacturing automation. Cambridge University Press, Cambridge

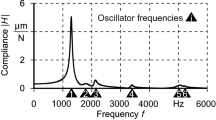

Biermann D, Surmann T, Kehl G (2008) Oszillatormodell für Werkzeugmaschinen zur Simulation von Zerspanprozessen. Entkopplung von Schwingungsmoden zur effizienten Berechnung der Prozessstabilität von Fertigungssystemen bei Einwirkung von Prozesskräften. wt Werkstattstechnik online 3:185–190

Altintas Y, Eynian M, Onozuka H (2008) Identification of dynamic cutting force coefficients and chatter stability with process damping. CIRP Ann-Manuf Technol 57(1):371–374

Turkes E, Orak S, Neseli S, Yaldiz S (2012) Decomposition of process damping ratios and verification of process damping model for chatter vibration. Measurement 45(6):1380–1386

Tyler CT, Schmitz TL (2013) Analytical process damping stability prediction. J Manuf Process 15(1):69–76

Kallage F (2007) Einsatz magnetischer Aktor- und Führungseinheiten zur Erhöhung der Bahngenauigkeit von Hochgeschwindigkeitsfräsmaschinen. Dr.-Ing. Diss., Leibniz Universität Hannover

Acknowledgments

The authors would like to thank the German Research Foundation (DFG) for their financial support of the presented research project (DE 447/80-1).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Denkena, B., Bickel, W. & Grabowski, R. Modeling and simulation of milling processes including process damping effects. Prod. Eng. Res. Devel. 8, 453–459 (2014). https://doi.org/10.1007/s11740-014-0544-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-014-0544-0