Abstract

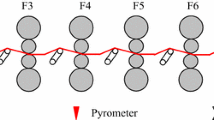

Thermal behavior and required power in hot continuous strip rolling are predicted by means of a coupled finite element-upper bound approach. A thermal-finite element analysis is utilized to simultaneously determine temperature distributions within the work-piece and the work-rolls while an upper bound solution is employed at the same time to estimate the rate of heat of deformation and the required power in each rolling stand. The proposed model can be applied for determining thermal behaviors of the strip and the work-rolls in single and multi- pass rolling schedules while the effects of different parameters including initial temperature and rolling speed can be considered in the analysis. To verify the predictions, the measured and predicted temperature–time diagrams during single- and double-pass rolling layout are compared and a reasonable agreement is observed.

Similar content being viewed by others

References

Bryant GF, Heselton MO (1982) Roll-gap temperature models for hot mills. Met Technol 9:469–477

Pietrzyk M, Lenard JG (1990) A study on heat transfer during flat rolling. Int J Numer Meth Eng 30:1459–1469

Sun CG, Yun CS, Chung HS, Hwang SM (1998) Investigation of thermo-mechanical behavior of a work roll and roll life in hot strip rolling. Metall Mater Trans A 29:2407–2424

Panjkovic V (2007) Model for prediction of strip temperature in hot strip steel mill. Appl Therm Eng 27:2404–2414

Tudball A, Brwon SGR (2006) Practical finite element heat transfer modelling for hot rolling of steels. Ironmak Steelmak 33:61–66

Martins PAF, Barata Marqes MJM (1999) Upper bound analysis of plane strain rolling using flow function and the weighted residual method. Int J Numer Methods Eng 44:1671–1683

Abrinia K, Fazlirad A (2010) Investigation of single pass shape rolling using an upper bound method. J Mater Eng Perform 19:541–552

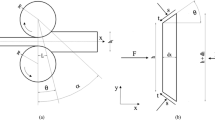

Serajzadeh S, Mahmoodkhani Y (2008) A combined upper bound and finite element model for prediction of velocity and temperature fields during hot rolling process. Int J Mech Sci 50:1423–1431

Sheikh H (2009) Thermal analysis of hot strip rolling using finite element and upper bound methods. Appl Math Model 33:2187–2195

Mansouri N, Mirhosseini M, Saboonchi A (2012) Thermal modeling of strip across the transfer table in the hot rolling process. Appl Therm Eng 38:91–104

Moon CH, Lee Y (2012) An approximate method for computing the temperature distribution over material thickness during hot flat rolling. Int J Heat Mass Transf 55:310–315

Chuang CH, Ju TM, Tseng AA (1995) The estimation of surface thermal behavior of the working roll in hot rolling process. Int J Heat Mass Transf 38:1019–1031

Hohnson RE, Keanini RG (1998) An asymptotic model of work roll heat transfer in strip rolling. Int J Heat Mass Transf 41:871–879

Lee JD, Manzari MT, Shen Y, Zeng W (2000) A 3D finite element approach to transient thermal analysis of work rolls in rolling process. Trans ASME J Manuf Sci Eng 122:706–716

Sonboli A, Serajzadeh S (2012) A model for evaluating thermo-mechanical stresses within work-rolls in hot-strip rolling. J Eng Math 72:73–85

Chen SJ, Tseng AA (1992) Spray and jet cooling in steel rolling. Int J Heat Fluid Flow 13:358–369

Huebner KH, Thornton EA (1982) The finite element method for engineers, 2nd edn. Wiley, New York

Hill R (1963) A general method of analysis for metal working processes. J Mech Phys Solids 11:305–326

Metals Handbook (1990) Properties and selection: nonferrous alloys and special-purpose materials, 10th edn. ASM International, Metals Park, Ohio

Prasad YVRK, Sasidhara S (eds) (1997) Hot working guide: a compendium of processing maps. ASM, Metals Park, pp 101–103

Lin YC, Chen XM (2011) A critical review of experimental results and constitutive descriptions for metals and alloys in hot working. Mater Des 32:1733–1759

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sayadi, H., Serajzadeh, S. Prediction of thermal responses in continuous hot strip rolling processes. Prod. Eng. Res. Devel. 9, 79–86 (2015). https://doi.org/10.1007/s11740-014-0577-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-014-0577-4