Abstract

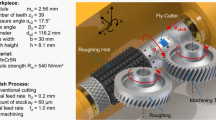

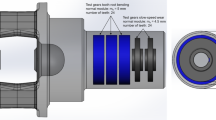

For a high durability of stressed gears profile accuracy, compressive residual stress and a high surface quality of the ground gear flanks is required. In this context the suitability of metal bonded cubic boron nitride (CBN) tools for discontinuous profile grinding of gears is examined. Metal bonded grinding tools usually provide a high wear resistance. Furthermore CBN has high thermal conductivity which can affect the residual stress state of the ground gear positively. In this context the influence of the CBN grain size, grain coating as well as the grain concentration on the ground gear surface and subsurface was investigated. For the examined grinding tools a bronze bonding system is used. A nickel coating of the CBN grains caused an enhanced embedding of the grains in the bond in comparison to the uncoated grains. For all tested tools and process parameters compressive residual stress could be measured as well as maximum height of roughness profile values around Rz = 4 µm.

Similar content being viewed by others

References

Denkena B, Köhler J, Schindler A, Woiwode S (2014) Continuous generating grinding: material engagement in gear tooth root machining. Mech Mach Theory 81:11–20

Heinzel C, Wagner A (2013) Fine finishing of gears with high shape accuracy. CIRP Ann Manuf Technol 62:359–362

Karpuschewski B, Knoche HJ, Hipke M (2008) Gear finishing by abrasive processes. CIRP Ann Manuf Technol 57:621–640

Köhler J, Schindler S, Woiwode S (2012) Continuous generating grinding: tooth root machining and use of CBN-tools. CIRP Ann 61:291–294

Denkena B, Köhler J, Schindler A, Woiwode S (2014) Kinematic analysis of the cutting speed for continuous generating grinding. Prod Eng. doi:10.1007/s11740-014-0578-3

Schenk T (2013) Verzahnungsschleifen mit abrichtbaren keramisch gebundenen CBN Schleifwerkeugen. 4th European Conference on Grinding

Kempa B (2000) Zahnflankenprofilschleifen mit galvanisch-gebundenem CBN. Dr.-Ing. Dissertation, RWTH Aachen

Bouke T (1994) Zahnflankenprofilschleifen mit keramisch-gebundenen CBN Schleifscheiben. Dr.-Ing. Dissertation, RWTH Aachen

Schlattmeier H (2003) Diskontinuierliches Zahnflankenprofilschleifen mit Korund. Dr.-Ing. Dissertation, RWTH Aachen

Türich A (2002) Werkzeug-Profilerzeugung für das Verzahnungsschleifen. Dr.-Ing. Dissertation, Universität Hannover

Denkena B, Köhler J, Woiwode S (2014) Dressing of vitrified bonded CBN tools for continuous generating grinding. Prod Eng 8:585–591

Holz R, Sauren J (1988) Schleifen mit Diamant und CBN. Vulkan-Verlag, Essen, 2. Auflage

Denkena B, Köhler J, Preising D, Woiwode S (2014) Hohe Oberflächengüten dank feiner CBN-Schleifscheiben. Werkstatt und Betrieb 6:60–63

Bargel H-J, Schulze G (2008) Werkstoffkunde. Springer, Berlin Heidelberg

Dies K (1967) Kupfer und kupferlegierungen in der technik. Springer, Berlin Heidelberg

Jackson MJ, Hitchiner MP (2011) Abrasive Tools and Bonding Systems. Springer Science+Business Media, LLC

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Denkena, B., Preising, D. & Woiwode, S. Gear profile grinding with metal bonded CBN tools. Prod. Eng. Res. Devel. 9, 73–77 (2015). https://doi.org/10.1007/s11740-014-0588-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-014-0588-1