Abstract

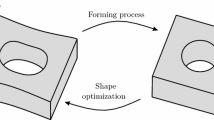

Inverse form finding aims in determining the optimal material configuration of a workpiece for a specific forming process. A gradient- and parameter-free (nodal-based) form finding approach has recently been developed, which can be coupled non-invasively as a black box to arbitrary finite element software. Additionally the algorithm is independent from the constitutive behavior. Consequently, the user has not to struggle with the underlying optimization theory behind. Benchmark tests showed already that the approach works robustly and efficiently. This contribution demonstrates that the optimization algorithm is also applicable to more sophisticated forming processes including orthotropic large strain plasticity, combined hardening and frictional contact. A cup deep drawing process with solid-shell elements and a combined deep drawing and upsetting process to form a functional component with external teeth are investigated.

Similar content being viewed by others

References

Merklein M, Allwood JM, Behrens BA, Brosius A, Hagenah H, Kuzmann K, Mori K, Tekkaya AE, Weckenmann A (2012) Bulk forming of sheet metal. CIRP Ann Manuf Technol 61(2):725–745

Guo YQ, Batoz JL, Detraux JM, Duroux P (1990) Finite element procedures for strain estimations of sheet metal forming parts. Int J Numer Methods Eng 30:1385–1401

Kim JY, Kim N, Huh MS (2000) Optimal blank design of an automobile subframe. J Mater Process Technol 101:31–41

Padmanabhan R, Oliveira MC, Baptista AJ, Alves JL, Menezes LF (2008) Blank design of deep drawing parts using parametric NURBS surfaces. J Mater Process Technol 101:31–41

Hammami W, Padmanabhan R, Oliveira MC, BelHadjSalah H, Alves JL, Menezes LF (2009) A deformation based blank design method for formed parts. Int J Mech Mater Des 5:303–314

Braibant V, Fleury C (1984) Shape optimal design using B-splines. Comput Methods Appl Mech Eng 194:3438–3452

Fourment L, Chenot JL (1990) Optimal design for non-steady-state metal forming processes—I. Shape optimization method. Int J Numer Methods Eng 39:33–50

Haftka R, Grandhi R (1986) Structural shape optimization—a survey. Comput Methods Appl Mech Eng 57–1:91–106

Michaleris P, Tortorelli D, Vidal C (1994) Tangent operators and design sensitivity formulations for transient non-linear coupled problems with application to elastoplasticity. Int J Numer Meth Eng 37–14:2471–2499

Acharjee S, Zabaras N (2006) The continuum sensitivity method for computational design of three-dimensional deformation processes. Comput Methods Appl Mech Eng 195:6822–6842

Govindjee S, Mihalic PA (1996) Computational methods for inverse finite elastostatics. Comput Methods Appl Mech Eng 136–1(2):47–57

Germain S, Landkammer P, Steinmann P (2014) On a recursive formulation for solving inverse form finding problems in isotropic elastoplasticity. Adv Model Simul Eng 10–1:1–19. doi:10.1186/2213-7467-1-10

Landkammer P, Steinmann P (2015) A non-invasive heuristic approach to shape optimization in forming. Comput Mech. doi:10.1007/s00466-015-1226-2

Landkammer P, Steinmann P (2015) Application of a non-invasive form finding algorithm to the ring compression test with varying friction coefficients. Key Eng Mater 651:1381–1386

Schneider T, Merklein M (2013) Manufacturing of geared sheet metal components by a single-stage Sheet-bulk metal forming process. In: Proceedings of conference competitive manufacturing, pp 177–182

Hinton E, Campbell JS (1974) Local and global smoothing of discontinuous finite element functions using a least squares method. Int J Numer Methods Eng 8–3:461–480

Landkammer P, Steinmann P (2015) A global damping factor for a non-invasive form finding algorithm. Proc Appl Math Mech 15–1:327–328

Grüner M, Merklein M (2014) Determination of friction coefficitions in deep drawing by modification of Siebels’s formula for calculation of ideal drawing force. Prod Eng Res Dev 8:577–584

Vierzigmann U, Koch J, Merklein M, Engel U (2012) Material flow in sheet-bulk metal forming. Key Eng Mater 504:1035–1040

Schmaltz S, Willner K (2014) Comparison of different biaxial tests for the inverse identification of sheet metal parameters. Strain Int J Exp Mech 50:5. doi:10.111/str.12080

Schmaltz S (2015) Inverse Materialparameter-identifikation von Blechwerkstoffen für ein anisotropes elasto-plastisches Materialmodell bei finiten Deformationen. Dissertation, Schriftenreihe Technische Mechanik 14, FAU Erlangen-Nürnberg

Alves de Souza RJ, Yoon JW, Cardoso RPR, Fontes Valente RA, Gracio JJ (2007) On the use of reduced enhanced solid-shell (RESS) elements for sheet forming simulations. Int J Plast 23:490–515

Löffler M, Schneider T, Vierzigmann U, Engel U, Merklein M (2015) Locally adapted tribological conditions as a method for influencing the material flow in Sheet-bulk metal forming processes. Key Eng Mater 639:267–274

Hildenbrand P, Schneider T, Merklein M (2015) Flexible rolling of process adapted semi-finished parts and its application in Sheet-bulk metal forming processes. Key Eng Mater 639:259–266

Yin Q, Soyarslan C, Grüner A, Brosius A, Tekkaya AE (2012) A cyclic twin bridge shear test for the identification of kinematic hardening parameters. Int J Mech Sci 59:31–43

Acknowledgments

This work was supported by the German Research Foundation (DFG) within the scope of the Transregional Collaborative Research Center on Sheet-Bulk Metal Forming (TCRC 73, https://www.tr-73.de) in the subprojects C3 (Parameter and Shape Optimization) and A1 (Deep Drawing).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Landkammer, P., Schneider, T., Schulte, R. et al. A non-invasive form finding method with application to metal forming. Prod. Eng. Res. Devel. 10, 93–102 (2016). https://doi.org/10.1007/s11740-016-0659-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-016-0659-6