Abstract

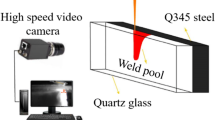

Spatters and pores that occur during laser deep penetration welding are unwanted defects that make post processing necessary. Therefore, these defects need to be avoided. The origin of pores and spatters are assumed to be in the process dynamics, especially the highly dynamic vapor channel. The keyhole is assumed to be responsible for producing these defects. Based on keyhole calculations from Part I, in this paper, calculated keyhole properties are correlated to pore and spatter formation observed during experiments. Spatters are recorded using a high speed camera and a spatter detection routine for measuring spatter speed, size and number per time. Pore number per time and pore sizes are detected using X-ray imaging after welding. Temporal spatter and pore characteristics can be correlated to dynamic values of the keyhole. The analytical model can predict spatter and pore formation depending on local frequencies and amplitudes in the keyhole. When using different beam profiles, extremely high local frequencies of the Top Hat beam at smaller keyhole dimensions seem to lead to an increased spatter and pore formation. The spring coefficient can be used as an indicator to predict spatter and pore characteristics.

Similar content being viewed by others

References

Mizutani M, Katayama S (2003) Keyhole behavior and pressure distribution during laser irradiation on molten metal. In: Proceedings of the 22nd international congress on applications of lasers and electro-optics (ICALEO), LIA congress proceeding. Paper 1004

Berger P, Hügel H, Graf T (2011) Understanding pore formation in laser beam welding. In: Schmidt M, Zaeh MF, Graf T, Ostendorf A (eds) Lasers in manufacturing (LIM), Physics Procedia, vol 12. Elsevier, Amsterdam, pp 241–247

Tsukamoto S, Kawaguchi I, Arakane G, Honda H (2002) Keyhole behavior in high power laser welding. In: Proceedings of the international congress on laser advanced materials processing (LAMP). International Society for Optics and Photonics

Fabbro R, Slimani S, Doudet I, Coste F, Briand F (2006) Experimental study of the dynamical coupling between the induced vapour plume and the melt pool for Nd–Yag CW laser welding. J Phys D Appl Phys 39:394–400

Zhang M, Chen G, Zhou Y, Li S (2013) Direct observation of keyhole characteristics in deep penetration laser welding with a 10 kW fiber laser. Opt Express 21(17):19997–20004

Seto N, Katayama S, Matsunawa A (2000) Porosity formation mechanism and suppression procedure in laser welding of aluminium alloys. Q J Jpn Weld Soc 18:243–255

Börner C, Dilger K, Rominger V, Harrer T, Krüssel T, Löwer T (2011) Influence of ambient pressure on spattering and weld seam quality in laser beam welding with the solid-state laser. In: Proceedings of 31st international congress on applications of lasers and electro-optics (ICALEO), LIA congress proceeding. Paper 1604

Fabbro R (2009) Limiting process for keyhole propagation during deep penetration laser welding. In: Proceeding of 5th international congress on laser advanced materials processing (LAMP)

Kawaguchi I, Tsukamoto S, Honda H, Arakane G (2003) Power modulation in deep penetration laser welding—optimization of frequency and waveform to prevent the porosity. In: Proceedings of 23rd international congress on applications of lasers and electro-optics (ICALEO), LIA congress proceeding. Paper 1006

Volpp J, Vollertsen F (2016) Keyhole stability during laser welding—Part I: modeling and evaluation. Prod Eng Res Devel 10:443–457

Volpp J, Vollertsen F (2015) Modeling keyhole oscillations during laser deep penetration welding at different spatial laser intensity distributions. Prod Eng Res Dev 9(2):167–178

Kaplan AFH, Powell J (2011) Spatter in laser welding. J Laser Appl 23(4):032005-1–032005-7

Berger P, Schuster R, Hügel H, Graf T (2010) Moving humps at the capillary front in laser welding. In: Proceedings of the 30th international congress on applications of lasers and electro-optics (ICALEO), LIA congress proceeding. Paper 106

Kaplan AFH (2015) Local flashing events at the keyhole front in laser welding. Opt Lasers Eng 68:35–41

Boley M, Weber R, Graf T (2015) Online detection of pore formation during laser deep-penetration welding. In: Proceeding of lasers in manufacturing congress (LIM)

Geiger M, Kägeler C, Schmidt M (2008) High-power laser welding of contaminated steel sheets. Prod Eng Res Dev 2:235–240

Acknowledgements

This work was accomplished within the Center of Competence for Welding of Aluminum Alloys (Centr-Al). Funding by the DFG—Deutsche Forschungsgemeinschaft (VO 530/52-2) is gratefully acknowledged. The “BIAS ID” numbers are part of the figures and allow the retraceability of the results with respect to mandatory documentation required by the funding organization.

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

See Figs. 18, 19, 20, 21 and 22.

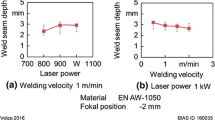

Spatters per second at different a welding velocities and b focal positions (based on reference parameters, Table 1; EN AW-1050)

Spatter sizes at different a welding velocities and b focal positions (based on reference parameters, Table 1; EN AW-1050)

Spatter speeds at different a welding velocities and b focal positions (based on reference parameters, Table 1; EN AW-1050)

Pores per second at different a welding velocities and b focal positions (based on reference parameters, Table 1; EN AW-1050)

Pore sizes at different a welding velocities and b focal positions (based on reference parameters, Table 1; EN AW-1050)

Rights and permissions

About this article

Cite this article

Volpp, J. Keyhole stability during laser welding—Part II: process pores and spatters. Prod. Eng. Res. Devel. 11, 9–18 (2017). https://doi.org/10.1007/s11740-016-0705-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-016-0705-4