Abstract

The usage and importance of titanium materials is increasing worldwide. Titanium is particularly suitable for use in turbines and lightweight construction due to its high heat resistance and low density. However, its low thermal conductivity results in machining problems and short tool life due to the associated high mechanical and thermal tool loads. Knowledge about the mechanical tool load during the milling process is of vital importance to process design and modeling. This paper presents multivariate regression method to model the process forces involved in the titanium milling process with respect to various technology parameters. In particular, the resulting tool wear and its relationships with these process forces is analyzed.

Similar content being viewed by others

Abbreviations

- A:

-

Cross section of undeformed chip (mm²)

- ae :

-

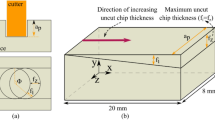

Width of cut (mm)

- ap :

-

Depth of cut (mm)

- Fc :

-

Cutting force (N)

- FcN :

-

Normal cutting force (N)

- Fx :

-

Force in x-direction (N)

- Fy :

-

Force in y-direction (N)

- fz :

-

Feed per tooth (mm)

- h:

-

Undeformed chip thickness (mm)

- K:

-

Intercept

- Kae:

-

Regression coefficient

- Kap:

-

Regression coefficient

- Kfz:

-

Regression coefficient

- Kvc:

-

Regression coefficient

- KVB:

-

Regression coefficient

- KA:

-

Regression coefficient

- V:

-

Material removal (cm3)

- VB:

-

Width of flank wear land VB (µm)

- vc :

-

Cutting speed (m/min)

- φ:

-

Entry angle (°)

References

Hanapia S, Tijania AS, Abdol Rahima AH, Wan Mohamed WAN (2015) Comparison of A prototype PEM fuel cell powertrain power demand and hydrogen consumption based on inertia dynamometer and on-road tests, 2015 International Conference on Alternative Energy in Developing Countries and Emerging Economies, Shah Alam, 2015

Pratap T, Patra K, Dyakonov AA (2015) Modeling cutting force in micro-milling of Ti-6Al-4V titanium alloy. Procedia Eng 129:134–139

Kappmeyer G, Hubig C, Hardy M, Witty M, Busch M (2012) Modern machining of advanced aerospace alloys —enabler for quality and performance. Procedia CIRP 1:28–43

López de Lacalle LN, Pérez J, Llorente JI, Sánchez JA (2012) Advanced cutting conditions for the milling of aeronautical alloys. J Mater Process Technol 100:1–11

Hasenfratz C, Abele E (2016) Analysis of the tool deflection in end milling of titanium, Proceedings of the ASME 2016 International Mechanical Engineering Congress ans Exposition, pp 1–13

M’Saoubi R, Axinte D, Soo LS, Nobel C, Attia H, Kappmeyer G, Engin S, Sim WM (2015) High performance cutting of advanced aerospace alloys and composite materials. CIRP Ann Manuf Technol 64(2):557–580

Ali MH, Khidhir BA, Ansari MNM, Mohamed B (2013) FEM to predict the effect of feed rate on surface roughness with cutting force during face milling of titanium alloy. HBRC J 9:263–269

Diana AC, Sorin MC (2013) Prediction of Cutting Forces at 2D Titanium Machining. Prodecia Eng 69:81–89

Martellotti ME (1941) An analysis of the milling process. Trans ASME 63:677

Altintas Y (2012) Manufacturing automation: metal cutting mechanics, machine tool vibrations, and CNC design. Cambridge University Press, Cambridge, New York

Sun S, Brandt M, Dargusch M (2009) Characteristics of cutting forces and chip formation in machining of titanium alloys. Int J Mach Tools Manuf 49:561–568

Rashid R, Sun S, Wang G, Dargusch M (2012) An investigation of cutting forces and cutting temperatures during laser-assisted machining of the Ti-6Cr-5Mo-5V-4Al beta titanium alloy. Int J Mach Tools Manuf 63:58–69

Germain D, Fromentin G, Poulachon G, Bissey-Breton S (2013) From large-scale to micromachining: a review of force prediction models. J Manuf Processes 15:389–401

Adetoro MB, Wen HP (2008) FEM evaluation of mechanistic cutting force coefficients using ALE Formation, Abaqus Users’ Conference, 2008

Taylor FW (1907) On the art of cutting metal. American society of mechanical engineers, New York

Kienzle O (1952) Die Bestimmung von Kräften und Leistungen an spanenden Werkzeugen und Werkzeugmaschinen. In: Zeitschrift des Vereins deutscher Ingenieure, pp 657–662

Kronenberg M (1954) Grundzüge der Zerspanungslehre; 1. Band: einschneidige Zerspanung. Springer, Berling, Göttingen, Heidelberg

Kalveram M (2005) Analyse und vorhersage der prozessdynamik und prozessstabilität beim Hochgeschwindigkeitsfräsen, PH.D. thesis, University Dortmund, Dortmund, 2005

Faassen R (2003) Prediction of regenerative chatter by modeling and analysis of high speed milling, Eindhoven, 2003

Sabberwal AJP (1962) Cutting forces in down milling. Int J Mach Tool Design Res 2:27–41

Fu HJ, Devor RE, Kapoor SG (1984) A mechanistic model for the prediction of the force system in face milling operations. J Manuf Sci Eng 106(1):81–88

Spiewak S (1995) An improved model of the chip thickness in milling. Ann CIRP 44(1):39–42

Wang H, Quin X, Ren C, Wang Q (2012) Prediction of cutting forces in helical milling process. Int J Adv Manuf Technol 58:849–859

Rott O, Hömberg D, Mense C (2006) A Comparison of analytical cutting force models. Forschungsverbund, Berlin

Kaymakci M, Kilic ZM, Altintas Y (2012) Unified cutting force model for turning, boring, drilling and milling operations. Int J Mach Tools Manuf 54–55:34–45

Ehmann KF, Kapoor SG, Devor RE, Lazoglu I (1997) Machining process modeling: a review. Trans ASME J Manuf Sci Eng 119(4B):655–663

Lv D, Xu J, Ding W, Fu Y, Yang C, Su H (2016) Tool wear in milling Ti40 burn-resistant titanium alloy using pneumatic mist jet impinging cooling. J Mater Process Technol 229:641–650

Klocke F, Settineri L, Lung D, Priarone PC, Arft M (2013) High performance cutting of gamma titanium aluminides: Influence of lubricoolant strategy on tool wear and surface integrity, Aachen, 2013

Nouari M., Iordanoff I (2007) Effect of the third-body particles on the tool–chip contact and tool-wear behaviour during dry cutting of aeronautical titanium alloys. Tribol Int 40:1351–1359

Oraby SE, Hayhurst DR (1991) Development of models for tool wear force relationships in metal cutting. Int J Mech Sci 33(2):125–138

Teitenberg TM, Bayoumi AE, Yucesan G (1992) Tool wear modeling through an analytic mechanistic model of milling processes. Wear 154(2):287–304

Lin SC, Yang RJ (1995) Force-based model for tool wear monitoring in face milling. Int J Mach Tools Manuf 35(9):1201–1211

Lin SC, Lin RJ (1996) Tool wear monitoring in face milling using force signals. Wear 198:136–142

Cui Y, Fussell BK, Jerard RB, Esterling DM (2009) Tool wear monitoring for milling by tracking cutting force model coefficients. Trans (NAMRI/SME) 37:S613–620

Kolar P, Sulitka M, Fojtu P, Falta J, Sindler J (2016) Cutting force modeling with a combined influence of tool wear and tool geometry. Manuf Technol 16(3):524–531

Acknowledgements

This research and development project is funded by the German Federal Ministry of Education and Research (BMBF) within the 02PN2205 and managed by the Project Management Agency Karlsruhe (PTKA). The authors are responsible for the contents of this publication. The authors are also grateful to the anonymous reviewers for their constructive criticisms which served to improve the paper.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Abele, E., Hasenfratz, C. & Bücker, M. Modeling of process forces with respect to technology parameters and tool wear in milling Ti6Al4V. Prod. Eng. Res. Devel. 11, 285–294 (2017). https://doi.org/10.1007/s11740-017-0739-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-017-0739-2