Abstract

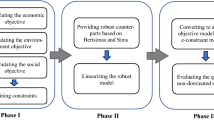

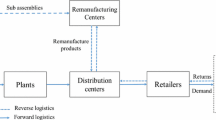

To come up with today’s competitive priorities, companies are always looking for new ways to optimize their processes. Integrated forward/reverse supply chain management is treated as a necessary response to the call for corporate sustainability in logistics networks. Also, due to growing environmental and economic concerns, the recycling of used products is becoming a common practice. It is recently remarkable that applying cross-docking in forward logistics has been recognized as an important field of performance improvement, however, approaches to consider this strategy in the both forward and reverse contexts (simultaneously) are far lacking. To cover these gaps, this paper indicates how cross-docking can be efficiently implemented in a forward/reverse structure, and in this regards, proposes an integrated multi-product supply chain network. To study the problem, we firstly present a mixed-integer linear programming (MILP) model to minimize total costs. Secondly, to solve the obtained model, we use the general algebraic modeling system (GAMS) software. Furthermore, the model performance is evaluated through comparing the case of using forward/reverse cross-docking with that of not applying this strategy (classical approach) in the network configuration—in terms of defining two theories. Finally, the significant outcomes resulted from utilizing forward/reverse cross-docking in the network are discussed. Considered the above requirements, the model increases the efficiency of the integrated forward/reverse logistics.

Similar content being viewed by others

References

Dondo RG, Méndez CA (2016) Operational planning of forward and reverse logistic activities on multi-echelon supply-chain networks. Comput Chem Eng 88:170–184

Amiri A (2006) Designing a distribution network in a supply chain system: formulation and efficient solution procedure. Eur J Oper Res 171(2):567–576

Kumar S, Putnam V (2008) Cradle to cradle: reverse logistics strategies and opportunities across three industry sectors. Int J Product Econ 115(2):305–315

Jayaraman V, Luo Y (2007) Creating competitive advantages through new value creation: a reverse logistics perspective. Acad Manag Perspect 21(2):56–73

Fernández AD, Gil MJA, Torre PG (2004). Logística inversa y medio ambiente. McGraw-Hill

Srivastava SK, Srivastava RK (2006) Managing product returns for reverse logistics. Int J Phys Distrib Logist Manag 36(7):524–546

Yu VF, Jewpanya P, Kachitvichyanukul V (2015). Particle swarm optimization for the multi-period cross-docking distribution problem with time windows. Int J Prod Res 1–17

Ladier AL, Alpan G (2015) Cross-docking operations: current research versus industry practice. Omega

Kheirkhah A, Rezaei S (2016). Using cross-docking operations in a reverse logistics network design: a new approach. Prod Eng 1–10

Zuluaga JPS, Thiell M, Perales RC (2016). Reverse cross-docking. Omega

Rezaei S, Kheirkhah A. A comprehensive approach in designing a sustainable closed-loop supply chain network using cross-docking operations. Computational and Mathematical Organization Theory, 1–48

Javid AA, Azad N (2010) Incorporating location, routing and inventory decisions in supply chain network design. Transp Res Part E Logist Transp Rev 46(5):582–597

Park S, Lee TE, Sung CS (2010) A three-level supply chain network design model with risk-pooling and lead times. Transp Res Part E Logist Transp Rev 46(5):563–581

Dowlatshahi S (2000) Developing a theory of reverse logistics. Interfaces 30(3):143–155

Rubio S, Chamorro A, Miranda FJ (2008) Characteristics of the research on reverse logistics (1995–2005). Int J Prod Res 46(4):1099–1120

Alpan G, Ladier AL, Larbi R, Penz B (2011) Heuristic solutions for transshipment problems in a multiple door cross docking warehouse. Comput Ind Eng 61(2):402–408

Boysen N, Fliedner M (2010) Cross dock scheduling: classification, literature review and research agenda. Omega 38(6):413–422

Ko HJ, Evans GW (2007) A genetic algorithm-based heuristic for the dynamic integrated forward/reverse logistics network for 3PLs. Comput Oper Res 34(2):346–366

Pati RK, Vrat P, Kumar P (2008) A goal programming model for paper recycling system. Omega 36(3):405–417

Zeballos LJ, Méndez CA, Barbosa-Povoa AP, Novais AQ (2014) Multi-period design and planning of closed-loop supply chains with uncertain supply and demand. Comput Chem Eng 66:151–164

Kalaitzidou MA, Longinidis P, Georgiadis MC (2015) Optimal design of closed-loop supply chain networks with multifunctional nodes. Comput Chem Eng 80:73–91

Van Belle J, Valckenaers P, Cattrysse D (2012) Cross-docking: state of the art. Omega 40(6):827–846

Lim A, Miao Z, Rodrigues B, Xu Z (2005) Transshipment through crossdocks with inventory and time windows. Naval Res Logist (NRL) 52(8):724–733

Musa R, Arnaout JP, Jung H (2010) Ant colony optimization algorithm to solve for the transportation problem of cross-docking network. Comput Ind Eng 59(1):85–92

Ma H, Miao Z, Lim A, Rodrigues B (2011) Crossdocking distribution networks with setup cost and time window constraint. Omega 39(1):64–72

Devika K, Jafarian A, Nourbakhsh V (2014) Designing a sustainable closed-loop supply chain network based on triple bottom line approach: a comparison of metaheuristics hybridization techniques. Eur J Oper Res 235(3):594–615

Yang XS, Deb S (2013) Multi-objective cuckoo search for design optimization. Comput Oper Res 40(6):1616–1624

McWilliams DL (2010) Iterative improvement to solve the parcel hub scheduling problem. Comput Ind Eng 59(1):136–144

Tonanont A, Yimsiri S, Jitpitaklert W, Rogers KJ (2008) Performance evaluation in reverse logistics with data envelopment analysis. In: Proceedings of the 2008 Industrial Engineering Research Conference, pp 764–769

Beamon BM (1999) Designing the green supply chain. Logistics information management 12(4):332–342

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rezaei, S., Kheirkhah, A. Applying forward and reverse cross-docking in a multi-product integrated supply chain network. Prod. Eng. Res. Devel. 11, 495–509 (2017). https://doi.org/10.1007/s11740-017-0743-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-017-0743-6