Abstract

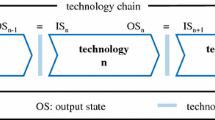

Existing methodologies in technology chain design are used to plan the deployment of manufacturing technologies under consideration of interactions between these technologies and workpiece properties. Present methodologies focus on workpiece characteristics which the technologies are designated to change. However, workpiece properties can also be negatively affected because of interactions between the manufacturing technologies and features which the technologies are not supposed to change. These undesired interactions can cause a lower quality of the produced parts and an increased amount of defective parts. In this paper, a new methodology is presented which enables the user to identify undesired interactions during the technology chain design process. Firstly, the product to be manufactured is analyzed and described as a set of individual features. Secondly, feature-specific technology chains are designed under consideration of possible undesired interactions. Thirdly, the individual feature-specific technology chains are merged to generate a robust technology chain for the manufacturing of the analyzed product. Since undesired interactions usually occur during production ramp-ups for the first time, the methodology is applied to a case study concerning a ramp-up in the automotive industry. In this context, improving the process stability by preventing the occurrence of undesired interactions is of high economic importance.

Similar content being viewed by others

References

Biermann D, Gausemeier J, Heim HP, Hess S, Petersen M, Ries A, Wagner T (2015) Planning and optimisation of manufacturing process chains for functionally graded components—part 2: case study on self-reinforced thermoplastic composites. Prod Eng Res Dev 9(3):405–416. doi:10.1007/s11740-015-0610-2

Milberg J, Müller S (2007) Integrated configuration and holistic evaluation of technology chains within process planning. Prod Eng Res Dev 1(4):401–406. doi:10.1007/s11740-007-0055-3

Doukas M, Psarommatis F, Mourtzis D (2014) Planning of manufacturing networks using an intelligent probabilistic approach for mass customised products. Int J Adv Manuf Technol 74(9–12):1747–1758. doi:10.1007/s00170-014-6121-z

Bikas C, Argyrou A, Pintzos G, Giannoulis C, Sipsas K, Papakostas N, Chryssolouris G (2016) An automated assembly process planning system. Proced CIRP 44:222–227

Klocke F, Fallböhmer M, Kopner A, Trommer G (2000) Methods and tools supporting modular process design. Robot Comput-Integr Manuf 16(6):411–423. doi:10.1016/S0736-5845(00)00024-7

Denkena B, Henjes J, Henning H (2011) Simulation-based dimensioning of manufacturing process chains. CIRP J Manuf Sci Technol 4(1):9–14. doi:10.1016/j.cirpj.2011.06.015

Klocke F, Müller J, Mattfeld P, Kukulies J, Stauder J (2016) Integrative technology and inspection planning of medical devices. Proced CIRP 51:105–110. doi:10.1016/j.procir.2016.05.097

Salomons O, Houten F, Kals H (1993) Review of research in feature-based design. J Manuf Syst 12(2):113–132. doi:10.1016/0278-6125(93)90012-I

Klocke F, Buchholz S, Stauder J (2014) Technology chain optimization: a systematic approach considering the manufacturing history. Prod Eng Res Dev 8(5):669–678. doi:10.1007/s11740-014-0572-9

Heller J, Feldhusen J (2014) Enhanced function structure applicability through adaptive function templates. Athens J Technol Eng 1(1):33–46

Suh N (2001) Axiomatic design. Advances and applications. Oxford University Press, New York

Roderburg A (2013) Methodik zur Entwicklung von hybriden Fertigungstechnologien. Dissertation, RWTH Aachen University

DIN ev (2003) DIN8580 Manufacturing processes—terms and definitions, division. Beuth, Berlin

Klocke F, Gorgels C, Stuckenberg A (2011) Investigations on surface defects in gear hobbing. Proced Eng 19:196–202. doi:10.1016/j.proeng.2011.11.101

Mang T, Bobzin K, Bartels T (2011) Industrial tribology. Tribosystems, friction, wear and surface engineering, lubrication. Wiley, Weinheim

Turunen E, Varis T, Gustafsson T, Keskinen J, Fält T, Hannula S (2006) Parameter optimization of hvof sprayed nanostructured alumina and alumina–nickel composite coatings. Surf Coat Techol 200(16–17):4987–4994. doi:10.1016/j.surfcoat.2005.05.018

Lyphout C, Nylen P, Östergren L (2012) Adhesion strength of HVOF sprayed IN718 coatings. J Therm Spray Technol 21(1):86–95. doi:10.1007/s11666-011-9689-y

Buchmann M, Gadow R, Lopez D, Scherer D (2002) Ceramic light metal composites—product development and industrial application. In: Lin HT, Singh M (eds) 26th Annual conference on composites, advanced ceramics, materials, and structures: b: ceramic en-gineering and science proceedings, 1st edn. The American Ceramic Society, Westerville, pp 103–113

Müller S (2008) Methodik für die entwicklungs- und planungsbegleitende Generierung und Bewertung von Produktionsalternativen. Dissertation, Technical University of Munich

Stauder J, Buchholz S, Mattfeld P, Rey J (2016) Evaluating the substitution risk of production systems in volatile environments. Prod Eng Res Dev 10(3):305–318. doi:10.1007/s11740-016-0670-y

Nau B, Roderburg A, Klocke F (2011) Ramp-up of hybrid manufacturing technologies. CIRP J Manuf Sci Technol 4(3):313–316. doi:10.1016/j.cirpj.2011.04.003

Acknowledgements

The authors would like to thank the German Research Foundation DFG for the support of the depicted research within “Graduiertenkolleg-Anlaufmanagement 1491” and within the Project KL 500/166-1 “Kostenoptimierte medizintechnische Herstellprozesse durch Integration von Technologie- und Prüfplanung (IMHOTEP)”.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Klocke, F., Mattfeld, P., Stauder, J. et al. Robust technology chain design: considering undesired interactions within the technology chain. Prod. Eng. Res. Devel. 11, 575–585 (2017). https://doi.org/10.1007/s11740-017-0756-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-017-0756-1