Abstract

Gears are integral and vital machine elements in the field of drive and transmission technology. With regard to economic and ecological aspects, cold forging represents a promising approach compared to conventional cutting processes for producing highly-loadable gears. A possible extrusion process for manufacturing helical gears is the so-called “Samanta”-process. In comparison to conventional extrusion processes, an additional ejector system is avoidable. Thus, in particular for helical gears, a negative impact on the gear quality by the ejector operation is prevented. Furthermore, the process chain during the component production cycle is shortened which leads to a more efficient production. The achievable gear accuracy as well as insufficient tool life are major challenges while establishing the “Samanta”-process in industry. To enable an industrial application, basic process understanding as well as knowledge about the influences on the process results is required. For influencing component and process properties within cold forging, approaches from the tribological system can be generally used. The aim of this study is to analyze the influence of the friction conditions on selected component and process properties within cold forging of gears by the “Samanta”-process. For adjusting the occurring friction, various lubrication systems were applied, which have been qualified using a double cup extrusion test (DCE-test). The results reveal that the lubrication system determines the friction conditions during forming. Within cold forging of helical gears by the “Samanta”-process, the friction influences the resulting strain hardening of the components and the required maximum forming force as well as the energy amount.

Similar content being viewed by others

References

Dudley DW (2013) Dudley’s handbook of practical gear design and manufacture. Springer, Berlin

Smith DJ (2003) Gear noise and vibration. Marcel Dekker Inc, New York

Gunasekaran A (1994) Improving productivity and quality in manufacturing organizations. Int J Prod Econ 36:169–183

Myeong-Sik J, Sang-Kon L (2013) Green manufacturing process for helical pinion gear using cold extrusion process. Int J Precis Eng Manuf 14:1007–1011

Doege E, Nägele H (1994) FE simulation of the precision forging process of bevel gears. Ann CIRP 43:241–244

Kaspar J (2017) Sustainable lightweight design—relevance and impact on the product development and lifecycle process. Procedia Manuf 8:409–416

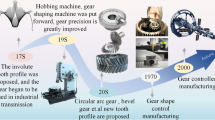

Samanta SK (1976) Helical gear: a novel method of manufacturing it. In: Proceedings of NAMRC IV, Columbus: Batelle Columbus Laboratories, pp 199–205

Schmieder F (1993) Beitrag zur Fertigung von schrägverzahnten Stirnrädern durch Querfließpressen. Dissertation, Universität Stuttgart

Odening D, Meyer M, Klassen A, Bouguecha A, Behrens B-A (2014) Präzisionsschmieden. In: Bach F-W, Kerber K (Hrsg) Prozesskette Präzisionsschmieden. Springer, Berlin

Lennartz J (1995) Kaltfließpressen von gerad- und schrägverzahnten Getriebewellen. Dissertation, RWTH Aachen

Koll W (1990) Kaltfließpressen von Bauteilen mit Verzahnungen. Dissertation, RWTH Aachen

DIN-Norm (1978) Toleranzen für Stirnradverzahnungen—Grundlagen. Deutsches Institut für Normen (DIN), DIN 3961. Beuth-Verlag, Berlin

Kiener C, Andreas K, Merklein M (2016) Basic numerical analysis of a “Samanta” based forward extrusion process. Adv Mater Res 1140:27–34

ICFG-Document (2013) Tool life and tool quality in cold forging, part five: surface finishing of cold forging tools. International Cold Forging Group (ICFG), Meisenbach, Bamberg (Doc. 23/13)

DIN 50320 (1979) Verschleiß; Begriffe, Systemanalyse von Verschleißvorgängen, Gliederung des Verschleißgebietes. Beuth, Düsseldorf

Schrader T, Shirgaokar M, Altan T (2007) A critical evaluation of the double cup extrusion test for selection of cold forging lubricants. J Mater Process Technol 189(3):1–3, 36–44

Buschhausen A, Weinmann K, Lee JY, Altan T (1992) Evaluation of lubrication and friction in cold forging using a double backward-extrusion process. J Mater Process Technol 33(1–2):95–108

Geiger R (1976) Der Stofffluss beim kombinierten Napffließpressen. In: Lange K (Hrsg) Berichte aus dem Institut für Umformtechnik, Universität Stuttgart, Bd. 36. Giradet, Essen

Tekkaya AE (2005) A guide for validation of FE-simulations in bulk metal forming. Ar J Sci Eng 30:113–136

VDI-Richtlinie (1984) Vorgespannte Preßwerkzeuge für das Kaltmassivumformen. Verein Deutscher Ingenieure (VDI), VDI 3176. VDI-Verlag, Düsseldorf

ICFG-Document (1987) General recommendations for design, manufacture and operational aspects of cold extrusion tools for steel. International Cold Forging Group (ICFG), Meisenbach, Bamberg (Doc. 6/82)

ICFG-Document (1991) Lubrication aspects in cold forging of carbon steels and low alloy steels. International Cold Forging Group (ICFG), Meisenbach, Bamberg (Doc. 8/91)

Bay N (2010) Green lubricants for metal forming. Tribology of manufacturing processes. In: Proceedings of the International Conference on tribology in manufacturing processes 1:5–33

Groche P, Müller C, Jahn A (2014) Effects of the tool lubrication in cold forging. Tribol Lett 53:599–605

Klocke F, Gorgels C, Kauffmann P, Herzhoff S, Schalster R, Stuckenberg A, Vasiliou V (2008) Trends in der Zahnradfertigung. In: Neugebauer R (Hrsg): Tagungsband zum 5. Chemnitzer Produktionstechnischen Kolloquium CPK: Zerspanung in Grenzbereichen, Berichte aus dem IWU. Band, Vol. 46, pp 87–113

Schöck J, Kammerer M (1999) Verzahnungsherstellung durch Kaltfließpressen. Umformtechnik 4:36–42

Acknowledgements

The authors would like to thank the research association “Green Factory Bavaria” for their financial support of the research project “Resource-efficient manufacturing of finished gears by cold forging”. Furthermore, the authors acknowledge the participating industrial partners within this project.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kiener, C., Neher, R. & Merklein, M. Influence of tribological conditions on cold forging of gears. Prod. Eng. Res. Devel. 12, 367–375 (2018). https://doi.org/10.1007/s11740-017-0785-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-017-0785-9