Abstract

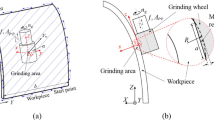

Through the kinematics involved on the grinding process, part of the grinding wheel topography is imprinted on the machined component in the form of grain scratches. During 5-axis grinding using spherical mounted points, the tilt \(\beta _{fN}\) and lead \(\beta _{f}\) angles can be used to locate the tool and align these scratches to achieve a desired angle in relation to the feed direction, creating a defined structure and decreasing the roughness on the ground surface. Moreover, different tool orientations change the force distribution over the tool, affecting the geometric deviation of the workpiece. The current work reveals a reduction of 50% of the roughness and geometric deviation for grinding of hot isostatically pressed silicon nitride HIPSN through optimization of the tilt \(\beta _{fN}\) and lead \(\beta _{f}\) angles.

Similar content being viewed by others

References

Uhlmann E, Borsoi Klein T, Mihotovic V (2008) Innovative schleifverfahren für die wirtschaftliche bearbeitung von hochleistungswerkstoffen. Industriediamantenrundschau (IDR) 42(4):22–34

Uhlmann E, Borsoi Klein T, Hochschild L, Bäcker C (2011) Influence of structuring by abrasive machining on the tribological properties of workpiece surfaces. Procedia Eng 19:363–370

Uhlmann E, Bäcker C, Schröer N (2013) Surface structuring using kinematic modulation in grinding. Prod Eng Res Dev 7(4):373–381

Borsoi Klein T (2015) Prozesstrategien beim NC-formschleifen mit schleifstiften. Doctoral Dissertation, Technische Universtät Berlin

Hennicke HW, Stein J (1989) Process of fine milling for ceramic materials. Mater Sci Eng A 109:3–7

Lim T-S, Lee C-M, Kim S-W, Lee D-W (2002) Evaluation of cutter orientations in 5-axis high speed milling of turbine blade. J Mater Process Technol 130–131:401–406

Hinduja S, Fan K-C (2007) Proceedings of the 35th international matador conference. Springer, London

Kuo K-L, Tsao C-C (2012) Rotary ultrasonic-assisted milling of brittle materials. Trans. Nonferrous Metals Soc. China 22:793–800

Schmidt C (2008) Kordinatenschleifen dentalkeramischer werkstoffe mit kleinen diamantwerkzeugen. Doctoral Dissertation, Technischen Hochschule Aachen

Denkena B, Koehler J, Turger A, Helmecke P, Correa T, Hurschler C (2013) Manufacturing conditioned wear of all-ceramic knee prostheses. Procedia CIRP 5:179–184

Uhlmann E, Borsoi Klein T, Koprowski S (2014) Tilt angle effects in surface grinding with mounted points. Prod Eng Res Dev 8(4):431–442

Gani EA, Kruth JP, Vanherck P, Lauwers B (1997) A geometrical model of the cut in five-axis milling accounting for the influence of tool orientation. Int J Adv Manuf Technol 13(10):677–684

Budak E, Ozturk E, Tunc LT (2009) Modeling and simulation of 5-axis milling processes. CIRP Ann Manuf Technol 58(1):347–350

Ozturk E, Tunc LT, Budak E (2009) Investigation of lead and tilt angle effects in 5-axis ball-end milling processes. Int J Mach Tools Manuf 49(14):1053–1062

Chen X, Zhao J, Dong Y, Han S, Li A, Wang D (2013) Effects of inclination angles on geometrical features of machined surface in five-axis milling. Int J Adv Manuf Technol 65(9–12):1721–1733

Luo S, Dong Z, Jun MB (2016) Optimal tool orientation generation and chip volume/cutting force predictions for 5-axis CNC machining of curved surfaces using flat-end mills. Comput Aided Des Appl 1:1–12

Fussell BK, Jerard RB, Hemmett JG (2003) Modeling of cutting geometry and forces for 5-axis sculptured surface machining. Comput Aided Des 35(4):333–346

Bohez EL, Ariyajunya B, Sinlapeecheewa C, Shein TMM, Lap DT, Belforte G (2007) Systematic geometric rigid body error identification of 5-axis milling machines. Comput Aided Des 39(4):229–244

Marinescu ID (2007) Handbook of advanced ceramics machining, 1st edn. CRC Press, Boca Raton

Uhlmann E, Koprowski S, Weingaertner WL, Rolon DA (2016) Modelling and simulation of grinding processes with mounted points: Part ii of ii—fast modelling method for workpiece surface prediction. Procedia CIRP 46:603–606

Denkena B, Köhler J, van der Meer M (2013) A roughness model for the machining of biomedical ceramics by toric grinding pins. CIRP J Manuf Sci Technol 6(1):22–33

Pinto FW (2008) An experimental and numerical approach to investigate the machining performance of engineered grinding tools. Doctoral Dissertation, Eidgenössische Technische Hochschule Zürich

Evans CJ, Bryan JB (1999) “Structured”, “textured” or “engineered” surfaces. CIRP Ann Manuf Technol 48(2):541–556

Ranjan R, Lambeth DN, Tromel M, Goglia P, Li Y (1991) Laser texturing for low-flying-height media. J Appl Phys 69(8):5745–5747

Denkena B, Kästner J, Wang B (2010) Advanced microstructures and its production through cutting and grinding. CIRP Ann Manuf Technol 59(1):67–72

Yan J, Zhang Z, Kuriyagawa T, Gonda H (2010) Fabricating micro-structured surface by using single-crystalline diamond endmill. Int J Adv Manuf Technol 51(9–12):957–964

Kim GM, Cho PJ, Chu CN (2000) Cutting force prediction of sculptured surface ball-end milling using z-map. Int J Mach Tools Manuf 40(2):277–291

Bouzakis K-D, Aichouh P, Efstathiou K (2003) Determination of the chip geometry, cutting force and roughness in free form surfaces finishing milling, with ball end tools. Int J Mach Tools Manuf 43(5):499–514

Lazoglu I (2003) Sculpture surface machining: a generalized model of ball-end milling force system. Int J Mach Tools Manuf 43(5):453–462

Lamikiz A, López de Lacalle LN, Sánchez JA, Salgado MA (2004) Cutting force estimation in sculptured surface milling. Int J Mach Tools Manuf 44(14):1511–1526

Acknowledgements

We would like to acknowledge the financial support given by CAPES Foundation (BEX-1094130), supported by the Ministry of Education, Brazil.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Koprowski, S., Uhlmann, E. & Weingaertner, W. Influence of tilt and lead angles on 5-axis grinding with spherical mounted points. Prod. Eng. Res. Devel. 12, 449–455 (2018). https://doi.org/10.1007/s11740-018-0812-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-018-0812-5