Abstract

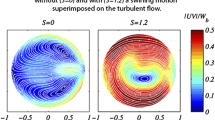

Three-component, turbulent flow measurements are performed using stereo PIV technique, in a cylindrical, stirred, water-flow mixer, with commercially available HR-100 as the impeller, which has three identical blades, separated by 120° with each other. The flow is analyzed at twelve axisymmetric, vertical planes, with the regular angular interval of 10°, so that the 12 planes cover the whole 120° separation between any two of the impeller blades. The results show that the turbulence mixing below the impeller is much higher than that above it, as the bulk fluid motion convects down the turbulence produced at the blade–water interfaces. Moreover, vortices with high level of turbulence, overwhelmingly dominated by the tangential velocity fluctuations, are created near the tips of the blades and convected downward, with their turbulence gradually dissipating with time. When these vortices are connected throughout the domain, they constitute three disconnected, helical arcs, each of which is connected to the tip of a blade and extends downward in the opposite direction to the rotation of the impeller. The arcs rotate with the same angular velocity of the impeller. The mean velocity and turbulence statistics of the flow are discussed at each of the alternate measurement planes.

Graphical Abstract

Similar content being viewed by others

Abbreviations

- PEG-400:

-

Polyethylene glycol, with the average molecular weight of 400

- RMS:

-

Root mean square value

- RPM:

-

Revolutions per minute

- RSS:

-

Reynolds shear stress e.g. \( {\text{RSS}}_{{u^{\prime}v^{\prime}}} \equiv{\overline{u^{\prime}v^{\prime}}} \) etc.

- TKE:

-

Turbulence kinetic energy ≡ \( \left( {\overline{u^{\prime}u^{\prime}}} +{\overline{v^{\prime}v^{\prime}}} +{\overline{w^{\prime}w^{\prime}}} \right)/2 \)

- TKE u′v′ :

-

≡ \( \left( {\overline{u^{\prime}u^{\prime}} +{\overline{ v^{\prime}v^{\prime}}}} \right)/2 \)

- 〈a〉:

-

Normalized value of any physical quantity, a

- \(\overline{a}\) :

-

Mean value of any physical quantity, a

- a′ :

-

Turbulence fluctuation in any physical quantity, a

- a RMS :

-

RMS of the turbulence fluctuations, a′

- D :

-

Mean diameter of the HR-100 impeller, 90 mm

- Re :

-

Reynolds number (defined as ωD2/2γ), 59,400

- \( \bar{V}_{uv}\) :

-

Two-dimensional mean velocity, which is defined as \( \sqrt {\bar{u}^{2} + \bar{v}^{2} } \)

- X :

-

Horizontal axis in rightward direction, with the origin lying on the central axis of the measurement tank

- Y :

-

Vertical axis in upward direction, with the origin located on the central axis of the measurement tank, 400 mm inside

- Z :

-

Direction perpendicular to the X–Y plane, considering a right-handed, cartesian coordinate system

- u :

-

X-component of the velocity

- v :

-

Y-component of the velocity

- w :

-

Z-component of the velocity

- γ:

-

Kinematic viscosity

- ε:

-

TKE dissipation rate per unit mass

- φ:

-

Angle between an axisymmetric, vertical, measurement plane and reference plane

- ω:

-

Impeller's rotation speed in clockwise direction, 15.7 rad/s

References

Bakker A, Myers KJ, Ward RW, Lee CK (1996) The laminar and turbulent flow patterns of a pitched blade turbine. Trans IChemE 74:485–491

Baldi S, Yianneskis M (2004) On the quantification of energy dissipation in the impeller stream of a stirred vessel from fluctuating velocity gradient measurements. Chem Eng Sci 59:2659–2671

Delafosse A, Collignon ML, Crine M, Toye D (2011) Estimation of the turbulent kinetic energy dissipation rate from 2D-PIV measurements in a vessel stirred by an axial Mixel TTP impeller. Chem Eng Sci 66:1728–1737

Doorne CWH, Westerweel J (2007) Measurement of laminar, transitional and turbulent pipe flow using stereoscopic-PIV. Exp Fluids 42:259–279

Ducci A, Yianneskis M (2005) Direct determination of energy dissipation in stirred vessels with two-point LDA. AlChE J 51:2133–2149

Kling K, Mewes D (2004) Two-color laser induced fluorescent for the quantification of micro- and macromixing in stirred vessels. Chem Eng Sci 59:1523–1528

Lamberto DJ, Alvarez MM, Muzzio FJ (1999) Experimental and computational investigation of the laminar flow structure in a stirred tank. Chem Eng Sci 54:919–942

Nilpawar AM, Reynolds GK, Salman AD, Hounslow MJ (2006) Surface velocity measurement in a high shear mixer. Chem Eng Sci 61:4172–4178

Rao MA, Brodkey RS (1972) Continuous flow stirred tank turbulence parameters in the impeller stream. Chem Eng Sci 27:137–156

Sharp K, Adrian R (2001) PIV study of small-scale structures around a Rushton turbine. AlChE J 47:766–778

Yoon HS, Sharp KV, Hill DF, Adrian RJ, Balachandar S, Ha MY, Kar K (2001) Integrated experimental and computational approach to simulation of flow in a stirred tank. Chem Eng Sci 56:6635–6649

Acknowledgments

The authors would like to deeply thank Mr. Kwon Young Park, a graduate student from Yokohama National University, Japan, for participating in the experiments carried out in this study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shekhar, C., Nishino, K., Yamane, Y. et al. Stereo-PIV measurement of turbulence characteristics in a flow mixer. J Vis 15, 293–308 (2012). https://doi.org/10.1007/s12650-012-0142-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12650-012-0142-1