Abstract

In order to better understand the flow characteristics of mixed-flow pump with non-uniform tip clearance, a test rig is established and the flow fields of various cross section in impeller are studied based on particle image velocimetry technology. The velocity vector distributions of three cross sections, e.g., impeller blade inlet, middle and outlet, were measured. The influences of flow rate and eccentricity on the flow fields of mixed-flow pump with non-uniform tip clearance were analyzed, and the relative velocity distribution of different positions at the same cross section is quantitatively discussed. The results show that the external characteristics have been greatly affected by the eccentricity of impeller. There is a significant negative correlation between eccentricity and efficiency. The maximum head and efficiency drop of eccentric impeller reach 11% and 20% separately. With the increase in eccentricity, the secondary flow phenomenon increases, such as backflow and vortex flow in impeller flow passage. Vortex structure is easily formed in the end wall region, which will give rise to backflow and even blocks the flow passage near impeller hub. The energy loss increases continuously in this process which is the main reason for the significant drop in efficiency. The research results are instructive for revealing the flow characteristics of flow fields of mixed-flow pump with non-uniform tip clearance.

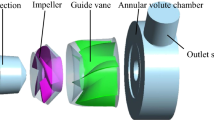

Graphic abstract

Similar content being viewed by others

References

Cao W, Li W, Ji L et al (2020) Research of transient rotor–stator interaction effect in a mixed-flow pump under part-load conditions. J Braz Soc Mech Sci Eng 42(1):36

Chen Z, Shi W, Zhang D, Zhang J, Zhang Z (2019) Experimental study on cavitation characteristics of mixed-flow pump during startup. J Drain Irrig Mach Eng 37(9):758–762

Feng J, Benra F, Dohmen HJ (2009) Time-resolved particle image velocity(PIV) measurements in a radial diffuser pump. In: Proceedings of the ASME 2009 fluids engineering division summer meeting/FEDSM 2009-78297, August 2–6, 2009, Colorado, USA

Hao Y, Tan L (2018) Symmetrical and unsymmetrical tip clearances on cavitation performance and radial force of a mixed flow pump as turbine at pump mode. Renew Energy 127:368–376

Issaka Z, Li H, Jiang Y et al (2019) Comparison of rotation and water distribution uniformity using dispersion devices for impact and rotary sprinklers. Irrig Drain 68(5):881–892

Ji L, Li W, Shi W (2017) Influence of different blade numbers on unsteady pressure pulsations of internal flow field in mixed-flow pump. J Drain Irrig Mach Eng 35(8):666–673

Ji L, Li W, Shi W (2020a) Influence of tip leakage flow and inlet distortion flow on a mixed-flow pump with different tip clearances within the stall condition. Proc Inst Mech Eng Part A J Power Energy 234(4):433–453

Ji L, Li W, Shi W et al (2020b) Energy characteristics of mixed-flow pump under different tip clearances based on entropy production analysis. Energy 199(2020):117447

Ji L, Li W, Shi W et al (2020c) Diagnosis of internal energy characteristics of mixed-flow pump within stall region based on entropy production analysis model. Int Commun Heat Mass 117(2020):104784

Lei Zhu, Daogao Wei, Wei Shi et al (2013) Effects of eccentricity on rotor dynamics characteristic of turbocharger. Chin J Automot Eng 3(4):282–286

Lei T, Zhiyi Y, Yun X, Yabin L, Shuliang C (2017) Role of blade rotational angle on energy performance and pressure fluctuation of a mixed-flow pump. Proc Inst Mech Eng Part A J Power Energy 231(3):227–238

Lei T, Zhifeng X, Yabin L et al (2018) Influence of T-shape tip clearance on performance of a mixed-flow pump. Proc Inst Mech Eng Part A J Power Energy 232(4):386–396

Li W, Leilei J, Shi W et al (2016a) Influence of different flow conditions on rotor axis locus of mixed-flow pump. Trans Chin Soc Agric Eng 32(4):91–97

Li W, Leilei J, Shi W et al (2016b) Experimental study on orbit of shaft centerline of mixed-flow pump during starting period. J Mech Eng 52(22):168–177

Li W, Ji L, Shi W, Zhou L, Zhang Y (2016c) PIV measurement of internal flow in mixed-flow pump under different flow rate conditions. Trans Chin Soc Agric Eng 32(24):82–88

Li W, Zhou L, Shi WD, Ji LL, Yang YF, Zhao XF (2017) PIV experiment of the unsteady flow field in mixed-flow pump under part loading condition. Exp Thermal Fluid Sci 83:191–199

Li W, Ji LL, Shi WD et al (2018a) Effect of a nonuniform radial/axial tip clearance on the flow field in a mixed-flow pump. Strength Mater 50(1):137–145

Li W, Ji L, Shi W et al (2018b) Vibration of shaft system in the mixed-flow pump induced by the rotor-stator interaction under partial load conditions. Shock Vib 2018(2):1–12

Li W, Ping Y, Shi W, Ji L, Li E, Ma L (2019a) Research progress in rotating stall in mixed-flow pumps with guide vane. J Drain Irrig Mach Eng 37(9):737–745

Li H, Issaka Z, Jiang Y et al (2019b) Influence of a fixed water dispersion device on jet dispersion and range from an impact sprinkler. Irrig Drain 68(4):669–678

Li W, Ji L, Shi W, Li E, Ma L, Yang Z (2020a) Particle image velocimetry experiment of the inlet flow field in a mixed-flow pump during the startup period. Proc Inst Mech Eng Part A J Power Energy 234(3):300–314

Li W, Li E, Ji L, Zhou L, Shi W, Zhu Y (2020b) Mechanism and propagation characteristics of rotating stall in a mixed-flow pump. Renew Energy 153:74–92

Li W, Ji L, Shi W, Zhou L, Chang H, Agarwal R (2020c) Expansion of high efficiency region of wind energy centrifugal pump based on factorial experiment design and computational fluid dynamics. Energies 13(2):483

Liu Y, Tan L (2018) Tip clearance on pressure fluctuation intensity and vortex characteristic of a mixed flow pump as turbine at pump mode. Renew Energy 129:606–615

Liu Y, Tan L (2019) Spatial–temporal evolution of tip leakage vortex in a mixed-flow pump with tip clearance. J Fluids Eng 141(8):081302

Lu G, Lu J, Qi D (2006) Experimental study on the flow in mixed pump impeller by PIV. Trans Chin Soc Agric Mach 37(10):53–57

Miner SM, Beaudoin RJ, Flack RD (1989) Laser velocimeter measurements in a centrifugal flow pump. J Turbomach 111(3):205–212

Nagahara T, Sato T, Kawabata S et al (2002) Effect of the submerged vortex cavitation in pump suction intake on mixed flow pump impeller. Turbomachinery 30:70–75

Paone N (1989) Experimental investigation of the flow in the vaneless diffuser of a centrifugal pump by particle image displacement velocimetry. Exp Fluids 7:371–378

Pedersen N, Larsen PS, Jacobsen CB (2003) Flow in a centrifugal pump impeller at design and off-design conditions-Part I: particle image velocimetry (PIV) and laser doppler velocimetry (LDV) measurements. J Fluids Eng 125(1):61–72

Qian L, Wei L, Leilei J et al (2017) The experimental research on axis orbit of mixed-flow pump. Trans Can Soc Mech Eng 41(5):745–757

Richert J, Nishiyama Y, Hata S et al (2011) The effect of casing geometry on rotordynamic fluid forces on a closed type centrifugal impeller in whirling motion. Int J Fluid Mach Syst 4(2):217–222

Shi W, Leilei J, Wei L et al (2016) PIV experiment on internal flow field of mixed-flow pump under different flow conditions. Trans Chin Soc Agric Mach 47(6):27–33

Shi B, Wei J, Zhang Y (2017) A novel experimental facility for measuring internal flow of Solid-liquid two-phase flow in a centrifugal pump by PIV. Int J Multiph Flow 89:266–276

Stickland MJ, Scanlon TJ, Waddell P et al (2003) Measurement of rotating flows using PIV and image derotation. Exp Fluids 34(2):304–306

Stoffel B, Ludwig G, Wei K (1992) Experimental investigations on the structure of part-load recirculations in centrifugal pump impellers and the role of different influences. Theor Exp Chem 24(4):482–486

Tang P, Li H, Issaka Z et al (2018) Effect of manifold layout and fertilizer solution concentration on fertilization and flushing times and uniformity of drip irrigation systems. Agric Water Manag 200:71–79

Wang L-H, Gao C-C, Chen D-X (2005) Flow visualization study on hydraulic pump-turbine. Water Power 31(7):61–63

Wei L, Leilei J, Weidong S, Yang Z, Ling Z (2016) Numerical calculation of internal flow field in mixed-flow pump with non-uniform tip clearance. Trans Chin Soc Agric Mach 47(10):66–72

Wu YL, Liu SH, Yuan HJ et al (2011) PIV measurement on internal instantaneous flows of a centrifugal pump. Sci China Technol Sci 54(2):270–276

Yang M, Wang D, Gao B et al (2016) Influences of guide vane-casing volute positions on performance of nuclear reactor coolant pump. J Drain Irrig Mach Eng 34(2):110–114

Yang S, Shao K, Dai T (2019) Influence of blade wrap angle on characteristics of mixed flow pump as turbine. J Drain Irrig Mach Eng 37(6):475–479

Zhang H, Shi W-D, Chen B et al (2014) Experimental study of flow field in interference area between impeller and guide vane of axial flow pump. J Hydrodyn 26(6):894–901

Zhang D, Shi W, Pan D et al (2015) Numerical and experimental investigation of tip leakage vortex cavitation patterns and mechanisms in an axial flow pump. J Fluids Eng 137(12):121103

Zhang N, Gao B, Li Z et al (2018) Unsteady flow structure and its evolution in a low specific speed centrifugal pump measured by PIV. Exp Thermal Fluid Sci 97:133–144

Zhang N, Liu X, Gao B et al (2019) Effects of modifying the blade trailing edge profile on unsteady pressure pulsations and flow structures in a centrifugal pump. Int J Heat Fluid Flow 75:227–238

Zhou L, Shi WD, Cao WD et al (2015) CFD investigation and PIV validation of flow field in a compact return diffuser under strong part-load conditions. Sci China Technol Sci 58(3):405–414

Zhou W, Qiu N, Wang L et al (2018) Dynamic analysis of a planar multi-stage centrifugal pump rotor system based on a novel coupled model. J Sound Vib 434:237–260

Zhou L, Deshpande K, Zhang X, Agarwal R (2020) Process simulation of chemical looping combustion using ASPEN plus for a mixture of biomass and coal with various oxygen carriers. Energy 195:116955

Zou Y, Ye SS, Wang YD et al (2016) CFD simulation and PIV measurement of liquid–liquid two-phase flow in pump-mix mixer. J Taiwan Inst Chem Eng 60:15–25

Acknowledgements

The work was sponsored by the National Natural Science Foundation of China (Nos.51679111, 51409127), Synergistic Innovation Center of Jiangsu Modern Agricultural Equipment and Technology(4091600014), National Key R&D Program Project (No.2017YFC0403703), PAPD, Key R&D Program Project in Jiangsu Province (BE2017126), Key R&D Program Project of Zhenjiang (No.SH2017049), Scientific Research Start Foundation Project of Jiangsu University (No.13JDG105) and Postgraduate Research & Practice Innovation Program of Jiangsu Province (KYCX19_1601).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, W., Ji, L., Shi, W. et al. Particle image velocimetry measurement of flow fields in a mixed-flow pump with non-uniform tip clearance. J Vis 24, 29–45 (2021). https://doi.org/10.1007/s12650-020-00686-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12650-020-00686-3