Abstract

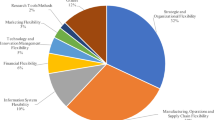

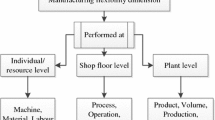

A high degree of flexibility is required for advancement in technology, rapid delivery to market, meeting customers demands and flexible manufacturing system is ideal for solving these problems. There are some variables which not only affect the flexibility but also affect each other. In this paper, twelve factors have been identified through the literature review and they are further analysed with the help of weighted interpretive structural modeling approach. In this research, a questionnaire based survey was conducted to rank these factors and ISM based approach has been employed to analyse their mutual interaction and interpretation of factors in terms of their driving and dependence powers has been examined. The structural model developed using this methodology helps to understand the interaction between various factors affecting the flexibility and their managerial implications. A method of effectiveness index is used to identify the key factors. The effectiveness index evaluated in this paper will help the industries to benchmark their performance by focussing on the factors reported in this paper.

Similar content being viewed by others

References

Anand V (2012) How to improve throughput in component conformance and maximize output. QuEST Global Services. www.quest-global.com/newsroom/CMM%20CoE.pdf

Attri R, Grover S, Dev N, Kumar D (2013a) Analysis of barriers of total productive maintenance (TPM). Int J Syst Assur Eng Manag 4(4):365–377

Attri R, Grover S, Dev N, Kumar D (2013b) An ISM approach for modelling the enablers in the implementation of total productive maintenance (TPM). Int J Syst Assur Eng Manag 4(4):313–326

Azzone G, Bertele U (1989) Measuring the economic effectiveness of flexible automation: a new approach. Int J Prod Res 27:735–746

Babu BS, Srinivasan G (2010) The impact of volume, routing and product mix flexibilities on the performance of a job shop: a simulation study. Int J Enterp Netw Manag 4(2):107–135

Bayazit O (2005) Use of AHP in decision-making for flexible manufacturing systems. J Manuf Technol Manag 16(7):808–819

Bernardo JJ, Mohamed Z (1992) The measurement and use of operational flexibility in the loading of flexible manufacturing systems. Eur J Oper Res 60:144–155

Beskese A, Kahraman C, Irani Z (2004) Quantification of flexibility in advanced manufacturing systems using fuzzy concept. Int J Prod Econ 89(1):45–56

Bolanos R, Fontela E, Nenclares A, Paster P (2005) Using interpretive structural modeling in strategic decision making groups. Manag Decis 43(6):877–895

Brill P, Mandelbaum M (1989) On measures of flexibility in manufacturing systems. Int J Prod Res 27(5):747–756

Browne J, Dubois D, Rathmill K, Sethi S, Stecke K (1984) Classification of flexible manufacturing systems. FMS Mag 2(2):114–117

Cardy RL, Krzystofiak FJ (1991) Interfacing high technology operations with blue collar workers: selection and appraisal in a computerized manufacturing setting. J High Technol Manag Res 2(2):193–210

Chan FTS (1999) Evaluations of operational control rules in scheduling a flexible manufacturing system. Robot Comput Integr Manuf 15(2):121–132

Chan FTS, Swarnkar R (2006) Ant colony optimization approach to a fuzzy goal programming model for a machine tool selection and operation allocation problem in an FMS. Robot Comput Integr Manuf 22(4):353–362

Chand M, Singh RK (2010) Study of select issues of supply chain management: a case study. Int J Adv Manuf Syst 1(2):151–155

Chand M, Raj T, Shankar R (2014a) Analysing the operational risks in supply chain by using weighted interpretive structural modeling (W-ISM) technique. Int J Serv Oper Manag 18(4):378–403

Chand M, Raj T, Shankar R (2014b) Analysing the operational risks in supply chain by using weighted interpretive structure modelling technique. Int J Serv Oper Manag 18(4):378–403

Chand M, Raj T, Shankar R (2015) Weighted-ISM technique for analysing the competitiveness of uncertainty and risk measures in supply chain. Int J Logist Syst Manag 21(2):181–198

Chen J-H, Ho S-Y (2005) A novel approach to production planning of flexible manufacturing systems using an efficient multi-objective genetic algorithm. Int J Mach Tools Manuf 45:949–957

Chung CH, Chen IJ (1989) A systematic assessment of the value of flexibility for an FMS. In: Stecke KE, Suri R (eds) Proceedings of the 3rd ORS4/TIMS conference on FMS. Elsevier Science Publishers, Amsterdam, pp 27–34

Chung CH, Chen IJ (1990) Managing the flexibility of Flexible Manufacturing System 10, competitive edge. In: Liberatore M (ed) Selection and evaluation at advanced manufacturing technologies. Springer-Verlag, Heidelberg, pp 280–305

Cleveland G, Schroeder RG, Anderson JC (1989) A theory of production competence. Decis Sci 20(4):655–668

Cordero R (1997) Changing human resources to make flexible manufacturing system (FMS) successful. J High Technol Manag Res 8(2):263–275

De Groote X (1988) The manufacturing/marketing interface. Wharton Decision Sciences, working paper No 88-09-06

Duperrin JC, Godet M (1973) Methode De Hierar Chization Des Elements D’um System. In: Proceedings of Rapport Economique De CEA. Paris, pp 45–51

Faisal MN, Banwat DK, Shankar R (2006) Supply chain risk mitigation: modeling the enablers. Bus Process Manag J 12(4):532–552

Faisal MN, Banwat DK, Shankar R (2007) Information risks management in supply chain: an assessment and mitigation framework. J Enterp Inf Manag 20(6):677–699

Farris DR, Sage AP (1975) On the use of interpretive structural modeling for worth assessment. Comput Electr Eng 2(2):149–174

Ficko M, Brezocnik M, Balic J (2004) Designing the layout of single- and multiple-rows flexible manufacturing system by genetic algorithms. J Mater Process Technol 157:150–158

Filote C, Ciufudean C (2010) Discrete event models for flexible manufacturing cells. In: Aized T (ed) Future manufacturing systems. In Tech. ISBN: 978-953-307-128-2. http://www.intechopen.com/books/future-manufacturing-systems/discrete-event-models-for-flexiblemanufacturing-cells

Grave S (1988) Safety stocks in manufacturing systems. J Manuf Oper Manag 1(1):67–101

Groover MP (2003) Automation, production systems and computer integrated manufacturing. Prentice-Hall, Inc, New Delhi

Inman RA (1991) Flexible manufacturing systems: issues and implementation. Ind Manag 31(4):7–11

Jain V, Raj T (2015) Modeling and analysis of FMS flexibility factors by TISM and fuzzy MICMAC. Int J Syst Assur Eng Manag 6(3):350–371

Jharkharia S, Shankar R (2004) IT enablement of supply chains: modelling the enablers. Int J Product Perform Manag 53(8):700–712

Jharkharia S, Shankar R (2005) IT enablement of supply chains: modeling the enablers. Int J Product Perform Manag 53(8):700–712

Kumar V (1987) Entropic measures of manufacturing flexibility. Int J Prod Res 25(7):957–966

Kumar S, Sharma RK (2015) An ISM based framework for structural relationship among various manufacturing flexibility dimensions. Int J Syst Assur Eng Manag 6(4):511–521

Kumar AP, Tiwari MK, Shankar R, Baveja A (2006) Solving machine-loading problem of a flexible manufacturing system with a constraint-based genetic algorithm. Eur J Oper Res 175(2):1043–1069

Malhotra MK, Grover V (1998) An assessment of survey research in POM: from constructs to theory. J Oper Manag 16(4):407–425

Malone DW (1975) An Introduction to the application of interpretive structural modelling. Proc IEEE 63:397–404

Mishra S, Datta S, Mahapatra SS (2012) Interrelationship of drivers for agile manufacturing: an Indian experience. Int J Serv Oper Manag 11(1):35–48

Nagar B, Raj T (2012) Analysis of critical success factors for implementation of humanised flexible manufacturing system in industries. Int J Logist Econ Glob 4(4):309–329

Nayak NK, Ray PK (2012) Production system flexibility and product quality relationships in manufacturing firm: an empirical research. Int J Strateg Eng Asset Manag 1(1):91–113

Ozbayrak M, Bell R (2003) A knowledge-based decision support system for the management of parts and tools in FMS. Decis Support Syst 35:487–515

Piore MJ, Sabel CF (1984) The second industrial divide: possibilities for prosperity. Basic Books, New York, p 203

Primrose PL, Verter V (1996) Do companies need to measure their production flexibility. Int J Oper Prod Manag 16(6):4–11

Qureshi MN, Kumar D, Kumar P (2007) Modeling the logistics outsourcing relationships variables to enhance shippers productivity and competitiveness in logistics supply chain. Int J Product Perform Manag 56(8):689–714

Raj T (2004) Improving productivity and flexibility of a machine shop by implementing AMT. Un-published M.E. Production Engineering Dissertation, Department of Mechanical Engineering, Delhi College of Engineering, Delhi University, India

Raj T, Shankar R, Suhaib M (2007) An ISM approach for modeling the enablers of flexible manufacturing system: the case of India. Int J Prod Res 46(24):1–30

Raj T, Shankar R, Suhaib M (2008) An ISM approach for modeling the enablers of flexible manufacturing system: the case for India. Int J Prod Res 46(24):6883–6912

Raj T, Shankar R, Suhaib M (2009) An ISM approach to analyse interaction between barriers of transition to flexible manufacturing system. Int J Manuf Technol Manage 16(4):417–438

Raj T, Attri R, Jain V (2012) Modeling the factors affecting flexibility in FMS. Int J Ind Syst Eng 11(4):350–374

Rao KVS, Deshmukh SG (1994) Strategic framework for implementing flexible manufacturing systems in India. Int J Oper Prod Manag 14(4):50–63

Ravi V, Shankar R (2005) Analysis of interactions among the barriers of reverse logistics. Technol Forecast Social Changes 72(8):1011–1029

Sethi AK, Sethi SP (1990) Flexibility in manufacturing: a survey. Int J Flex Manuf Syst 2(4):289–328

Sharma S, Terence AS, Shin J (1995) Consumer ethnocentrism: a test of antecedents and moderators. J Acad Mark Sci 23(1):26–37

Singh RK (2011) Developing the framework for coordination in supply chain of SMEs. Bus Process Manag J 17(4):619–638

Singh R, Garg S (2007) Interpretive structural modeling of factors for improving competitiveness of SMEs. Int J Product Qual Manag 2(4):423–440

Singh MD, Kant R (2008) Knowledge management barriers: an interpretive structural modeling approach. Int J Manag Sci Eng Manag 3(2):141–150

Singh MD, Shankar R, Narain R, Agarwal A (2003) An interpretive structural modeling of knowledge management in engineering industries. J Adv Manag Res 1(1):28–40

Singholi A, Ali M, Sharma C (2012) Impact of manufacturing flexibility on FMS performance: a simulation study. Int J Ind Syst Eng 10(1):96–116

Singholi A, Ali M, Sharma C (2013) Evaluating the effect of machine and routing flexibility on flexible manufacturing system performance. Int J Serv Oper Manag 16(2):240–261 (ISSN:1744-2389)

Soon YK, Park CS (1987) Economic measure of productivity, quality and flexibility in advanced manufacturing systems. J Manuf Syst 6(3):193–207

Spano MR, O’Grady PJ, Young RE (1993) The design of flexible manufacturing systems. Comput Ind 21:185–198

Subramanian C, Chandrasekaran M, Govind DS (2010) Analyzing the buyer supplier relationship factors: an integrated modeling approach. Int J Manag Sci Eng Manag 5(4):292–301

Sujono S, Lashkari RS (2007) A multi-objective model of operation allocation and material handling system selection in FMS design. Int J Prod Econ 105:116–133

Swamidass P (1988) Manufacturing flexibility. Monograph No. 2. Operations Management Association

Thakkar J, Deshmukh SG, Gupta AD, Shankar R (2007) Development of score card: an integrated approach of ISM and ANP. Int J Product Perform Manag 56(1):25–59

Thakkar J, Kanda A, Deshmukh SG (2008) Evaluation of buyer-supplier relationships using an integrated mathematical approach of interpretive structural modeling (ISM) and graph theoretic approach. J Manuf Technol Manag 19(1):92–124

Tonn B, Peretz JH (2007) State level benefits of energy efficiency. Energy Policy 35:3665–3674

Verma RK (2014) Implementation of interpretive structural model and topsis in manufacturing industries for supplier selection. Ind Eng Lett 4(5):1–8

Warfield JN (1973) Binary matrices in systems modeling. IEEE Trans Syst Men Cybern 3(5):441–449

Warfield J (1974) Developing interconnected matrices in structural modelling. IEEE Trans Syst Men Cybern 4(1):51–81

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gothwal, S., Raj, T. Analyzing the factors affecting the flexibility in FMS using weighted interpretive structural modeling (WISM) approach. Int J Syst Assur Eng Manag 8, 408–422 (2017). https://doi.org/10.1007/s13198-016-0443-1

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13198-016-0443-1