Abstract

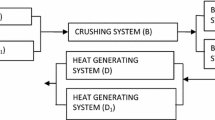

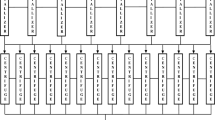

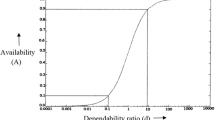

A sugar manufacturing plant is a complex industrial system having five subsystems arranged in a series configuration and each subsystem followed a different failure rate. Upon ensues of a random failure, the failed subsystem stops working and forces the complete system to stop and results in a downstate of the plant. The impact of downstate directly influences the production of plant and its reliability. Here, a reliability and maintainability analysis of the sugar manufacturing plant has been carried out at the subsystem and plant level. Data collection has been performed for six months from the sugar plant and descriptive statistical analysis has been made for time to repair and time between failures. The best-fitted distribution and parameters were determined along with trend and serial correlation analysis to attain the best performance of the plant. Additionally, graphs for reliability and hazard rate modes for five subsystems and the entire plant were depicted. The suggested models might be a suitable tool towards (a) considering the recent conditions, and (b) forecasting reliability for refining the sugar manufacturing plant by applying proper maintenance policy.

Similar content being viewed by others

References

Aggarwal A, Kumar S, Singh V (2015) Performance modeling of the skim milk powder production system of a dairy plant using RAMD analysis. Int J Quality Reliab Manage 32(2):167–181

Arvanitoyannis IS, Traikou A (2005) Implementation of HACCP to bread and fine based industry. Critical Rev Food Sci Nutr 45(5):327–370

Barabady, J, 2005. Reliability and maintainability analysis of crushing plants in Jajarm Bauxite Mine of Iran. In Proceedings of the annual reliability and maintainability symposium, USA, pp. 109–115.

Barak MS, Barak SK (2018) Profit analysis of a two-unit cold standby system model operating under different weather conditions. Life Cycle Reliab Safety Eng 7(3):173–183

Barak, M. S., and SUDESH KUMARI. "Profit Analysis of a Two Unit Cold Standby System Operating Under Different Weather Conditions Subject to Inspection." Applications & Applied Mathematics 13, no. 1 (2018)."

Barak MS, Yadav D, Barak SK (2018) Stochastic analysis of a two-unit redundant system with priority to inspection over the repair. Life Cycle Reliab Safety Eng 7(2):71–79

Barak MS, Garg R, Kumar A (2021) Reliability measures analysis of a milk plant using RPGT. Life Cycle Reliab Safety Eng. https://doi.org/10.1007/s41872-020-00163-8

Chillar, S (2014). Analysis of System Reliability Models Subject to Degradation and Random Shocks. Ph.D. thesis. M.D. University, Rohtak.

Crow LH (1974) Reliability analysis for complex, repairable systems. In: Proschan F, Serfling RJ (eds) Reliability and Biometry. SIAM, Philadelphia, pp 379–410

Dahiya O, Kumar A, Saini M (2019) Mathematical modeling and performance evaluation of A-Pan crystallization system in the sugar industry. SN Appl Sci. https://doi.org/10.1007/s42452-019-0348-0

Dai Y, Zhou Y-F, Jia YZ (2003) Distribution of time between failures of machining center based on type I censored data. Reliab Eng Syst Saf 79(3):377–379

Devi, K (2019). Analysis of Redundant System of Non-identical Units using Weibull Distribution. Ph.D. thesis. Manipal University Jaipur, Jaipur.

Diallo M, Perreval H, Quillot A (2001) Manufacturing cell design with flexible routing capability in presence of unreliable machines. Int J Prod Econ 74(1–3):175–182

Ebeling A (2000) An introduction to reliability and maintainability engineering. New Delhi: Tata Mcgraw Hill Company Ltd.

https://en.wikipedia.org/wiki/Log-normal_distribution#media/File:PDF-log_normal _distributions. SVG

Kadyan S, Barak MS (2020) Stochastic analysis of a non-identical repairable system of three units with priority for operation and simultaneous working of cold standby units. Int J Statist Reliab Eng 7(2):269–274

Kadyan MS, Kumar R (2015) Availability and profit analysis of a feeding system in the sugar industry. Int J Syst Assurance Eng Manage 8(1):301–316

Kadyan MS, Kumar R (2017) Availability based operational behavior of B-Pan crystallization system in the sugar industry. Int J Syst Assurance Eng Manage. https://doi.org/10.1007/s13198-017-0614-8

Kumar, R (2015). Availability and profit analysis of sugar industrial systems. Ph.D. thesis. Kurukshetra University, Kurukshetra.

Kumar A, Saini M (2018) Mathematical modeling of sugar plant: a fuzzy approach. Life Cycle Reliab Safety Eng 7(1):11–22

Liberopoulos G, Tsarouhas P (2002) Systems analysis speeds up Chipita’s food processing line. Interfaces 32(3):62–76

Liberopoulos G, Tsarouhas P (2005) Reliability analysis of an automated pizza processing line. J Food Eng 69(1):79–96

Malik SC, Yadav RK, Barak MS (2021) Stochastic analysis of a unit wise redundant computer system with priority to hardware repair and failure of service facility during software up-gradation. Int J Statist Reliab Eng 7(3):342–349

MIL-HDBK-189 (1981), “Reliability growth management”, Headquarters, US Army Communication Research and Development Command, ATTN: DRDCO-PT, Fort Monmouth, NJ.

Saini M, Kumar A (2019) Performance analysis of evaporation system in sugar industry using RAMD analysis. J Braz Soc Mech Sci Eng 41:4

Seifoddini S, Djassemi M (2001) The effect of reliability consideration on the application of the quality index. Comput Ind Eng 40(1–2):65–77

Tsarouhas P (2018) Reliability, availability, and maintainability (RAM) analysis for wine packaging production line. Int J Quality Reliab Manage 35(3):821–842

Tsarouhas P (2019) Statistical analysis of failure data for estimating reliability, availability, and maintainability of an automated croissant production line. J Qual Maint Eng. https://doi.org/10.1108/JQME-04-2018-0029

Tsarouhas P, Arvanitoyannis L (2011) Quantitative analysis for peach production line management. J Food Eng 105(2011):28–35

Tsarouhas P, Besseris G (2017) Maintainability analysis in shaving blades industry: a case study. Int J Quality Reliab Manage 34(4):581–594

Varzakas T, Arvanitoyannis IS (2007) Application of failure mode & effect analysis (FMEA), cause & effect analysis, and Pareto diagram in conjunction with HACCP to a strudel manufacturing plant. Int J Food Sci Technol 42:1156–1176

Waghmode LY, Patil RB (2016) Reliability analysis and life cycle cost optimization: a case study from Indian industry. Int J Quality Reliab Manage 33(3):414–429

Wang YQ, Jia YZ, Jiang WW (2001) Early failure analysis of machining centers: a case study. Reliab Eng Syst Saf 72(1):91–97

Zerwick AY (1996) A focussed approach to reliability, availability, and maintainability for critical pressure vessels and piping. Int J Press Vessels Pip 66:155–160

Funding

The present work was not supported by any funding agency.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The Authors declare that they have no conflict of interest.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Informed consent

Informed consent was obtained from all individual participants included in the study.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Saini, M., Kumar, A. & Sinwar, D. Parameter estimation, reliability and maintainability analysis of sugar manufacturing plant. Int J Syst Assur Eng Manag 13, 231–249 (2022). https://doi.org/10.1007/s13198-021-01216-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13198-021-01216-6