Abstract

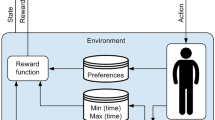

Assembly lines are at the core of many manufacturing systems, and planning for a well-balanced flow is key to ensure long-term efficiency. However, in flexible configurations such as Multi-Manned Assembly Lines (MMAL), the balancing problem also becomes more challenging. Due to the increased relevance of these assembly lines, this work aims to investigate the MMAL balancing problem, to contribute for a more effective decision-making process. Therefore, a new approach is proposed based on Deep Reinforcement Learning (DRL) embedded in a Digital Twin architecture. The proposed approach provides a close-to-reality training environment for the agent, using Discrete Event Simulation to simulate the production system dynamics. This methodology was tested on a real-world instance with preliminary results showing that similar solutions to the ones obtained using optimization-based strategies are achieved. This research provides evidence of success in terms of dynamic resource assignment to tasks and workers as a basis for future developments.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Scholl, A., Becker, C.: State-of-the-art exact and heuristic solution procedures for simple assembly line balancing. Eur. J. Oper. Res. 168(3), 666–693 (2006)

Battaïa, O., Dolgui, A.: A taxonomy of line balancing problems and their solution approaches. Int. J. Prod. Econ. 142(2), 259–277 (2013)

Jiao, Y., Jin, H., Xing, X., Li, M., Liu, X.: Assembly line balance research methods, literature and development review. Concurr. Eng. 29(2), 183–194 (2021)

Dimitriadis, S.G.: Assembly line balancing and group working: a heuristic procedure for workers’ groups operating on the same product and workstation. Comput. Oper. Res. 33(9), 2757–2774 (2006)

Mnih, V., Silver, D., Riedmiller, M.: Playing Atari with Deep Reinforcement Learning. arXiv Prepr. arXiv1312.5602, pp. 1–9 (2013)

Silver, D., et al.: Mastering Chess and Shogi by Self-Play with a General Reinforcement Learning Algorithm. no. arXiv:1712.01815. arXiv (2017)

Gomez, D., Quijano, N., Giraldo, L.F.: Learning Transferable Concepts in Deep Reinforcement Learning. no. arXiv:2005.07870. arXiv (2020)

Speck, D., Biedenkapp, A., Hutter, F., Mattmüller, R., Lindauer, M.: Learning heuristic selection with dynamic algorithm configuration. Proc. Int. Conf. Autom. Plann. Schedul. 31, 597–605 (2021)

Priore, P., Gómez, A., Pino, R., Rosillo, R.: Dynamic scheduling of manufacturing systems using machine learning: an updated review. Artif. Intell. Eng. Des. Anal. Manuf. 28(01), 83–97 (2014)

Cunha, B., Madureira, A.M., Fonseca, B., Coelho, D.: Deep reinforcement learning as a job shop scheduling solver: a literature review. In: Madureira, A.M., Abraham, A., Gandhi, N., Varela, M.L. (eds.) HIS 2018. AISC, vol. 923, pp. 350–359. Springer, Cham (2020). https://doi.org/10.1007/978-3-030-14347-3_34

Lv, Y., Tan, Y., Zhong, R., Zhang, P., Wang, J., Zhang, J.: Deep reinforcement learning‐based balancing and sequencing approach for mixed model assembly lines. IET Collab. Intel. Manufact. 4(3), 181–193 (2022)

Papacharalampopoulos, A., Stavropoulos, P.: Manufacturing process optimization via digital twins: definitions and limitations. In: Kim, K.-Y., Monplaisir, L., Rickli, J. (eds.) Flexible Automation and Intelligent Manufacturing: The Human-Data-Technology Nexus: Proceedings of FAIM 2022, June 19–23, 2022, Detroit, Michigan, USA, pp. 342–350. Springer International Publishing, Cham (2023). https://doi.org/10.1007/978-3-031-18326-3_33

Arrais, R., et al.: Application of the open scalable production system to machine tending of additive manufacturing operations by a mobile manipulator. In: Moura Oliveira, P., Novais, P., Reis, L.P. (eds.) EPIA 2019. LNCS (LNAI), vol. 11805, pp. 345–356. Springer, Cham (2019). https://doi.org/10.1007/978-3-030-30244-3_29

Brockman, G., et al.: ‘Openai gym’, arXiv Prepr. arXiv1606.01540 (2016)

Schulman, J., Wolski, F., Dhariwal, P., Radford, A., Klimov, O.: Proximal Policy Optimization Algorithms

Şahin, M., Kellegöz, T.: Balancing multi-manned assembly lines with walking workers: problem definition, mathematical formulation, and an electromagnetic field optimisation algorithm. Int. J. Prod. Res. 57(20), 6487–6505 (2019)

Acknowledgments

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 952003.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Santos, R., Marques, C., Toscano, C., Ferreira, H.M., Ribeiro, J. (2024). Deep Reinforcement Learning-Based Approach to Dynamically Balance Multi-manned Assembly Lines. In: Silva, F.J.G., Pereira, A.B., Campilho, R.D.S.G. (eds) Flexible Automation and Intelligent Manufacturing: Establishing Bridges for More Sustainable Manufacturing Systems. FAIM 2023. Lecture Notes in Mechanical Engineering. Springer, Cham. https://doi.org/10.1007/978-3-031-38241-3_71

Download citation

DOI: https://doi.org/10.1007/978-3-031-38241-3_71

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-38240-6

Online ISBN: 978-3-031-38241-3

eBook Packages: EngineeringEngineering (R0)