Abstract

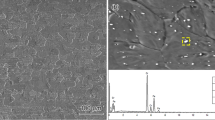

Corrosion behavior of joined Ti-B4C composites was evaluated in 9 g/L NaCl solution using cyclic polarization and electrochemical impedance spectroscopy. Tribocorrosion behavior was investigated by sliding against an alumina ball under open-circuit potential and potentiodynamic polarization. The results showed that joining did not negatively affect the corrosion behavior of the composites. Regarding tribocorrosion, while joining did not significantly influence the coefficient of friction and total wear volume loss, it resulted in slightly increased electrochemical activity under sliding. These results showed that brazing may be considered as a simple and low-cost technique for joining Ti-B4C composites to be operated in tribocorrosive environments.

Similar content being viewed by others

References

N. Chawla and K.K. Chawla, Metal Matrix Composites, Kluwer Academic Publishers, Boston, 2006

K. Morsi and V.V. Patel, Processing and Properties of Titanium-Titanium Boride (TiBw) Matrix Composites—A Review, J. Mater. Sci., 2007, 42, p 2037–2047

F. Toptan, A. Rego, A.C. Alves, and A. Guedes, Corrosion and Tribocorrosion Behavior of Ti-B4C Composite Intended for Orthopaedic Implants, J. Mech. Behav. Biomed. Mater., 2016, 61, p 152–163. https://doi.org/10.1016/j.jmbbm.2016.01.024

E. Gordo, R.G. das Neves, B. Ferrari, A. Jiménez-Morales, A. Lima, A.C. Alves, A.M. Pinto, and F. Toptan, Corrosion and Tribocorrosion Behavior of Ti-Alumina Composites, Key Eng. Mater., 2016, 704, p 28–37. https://doi.org/10.4028/www.scientific.net/KEM.704.28

J.I. Silva, A.C. Alves, A.M. Pinto, and F. Toptan, Corrosion and Tribocorrosion Behavior of Ti-TiB-TiNx In-Situ Hybrid Composite Synthesized by Reactive Hot Pressing, J. Mech. Behav. Biomed. Mater., 2017, 74, p 195–203

L. Rangaraj, K. Barman, C. Divakar, and V. Jayaram, Reactive Hot Pressing of Ti-B-C and Ti-C at 1200 °C, Ceram. Int., 2013, 39, p 5955–5961

W.P. Weng and T.H. Chuang, Interfacial Characteristics for Brazing of Aluminum Matrix Composites with Al-12Si Filler Metals, Metall. Mater. Trans. A Phys. Metall. Mater. Sci., 1997, 28(12), p 2673–2682

M. Aydin, R. Gürler, and M. Türker, The Diffusion Welding of 7075Al-3%SiC Particles Reinforced Composites, Phys. Met. Metallogr., 2009, 107(2), p 206–210

A.A.M. da Silva, A. Meyer, J.F. dos Santos, C.E.F. Kwietniewski, and T.R. Strohaecker, Mechanical and Metallurgical Properties of Friction-Welded TiC Particulate Reinforced Ti-6Al-4V, Compos. Sci. Technol., 2004, 64(10–11), p 1495–1501

J.C. Yan, H.B. Xu, L. Shi, X.L. Wang, and S.Q. Yang, Vibration Assisted Brazing of SiCp/A356 Composites: microstructure and Mechanical Behaviour, Sci. Technol. Weld. Join., 2008, 13(8), p 760–764. https://doi.org/10.1179/136217108X333318

M.M. Schwartz, Introduction to Brazing and Soldering, ASM Handbook Volume 6: Welding, Brazing, and Soldering, D.L. Olson, T.A. Siewert, S. Liu, and G.R. Edwards, Ed., ASM International, Materials Park, OH, 1993, p 109–114

J. Ba, X.H. Zheng, R. Ning, J.H. Lin, J.L. Qi, J. Cao, W. Cai, and J.C. Feng, Brazing of SiO2-BN Modified with In Situ Synthesized CNTs to Ti6Al4V Alloy by TiZrNiCu Brazing Alloy, Ceram. Int., 2018, 44(9), p 10210–10214

G.H. Han, Y.F. Wang, H.Y. Zhao, X.G. Song, J. Cao, and J.C. Feng, Vacuum Brazing of TZM Alloy to ZrC Particle Reinforced W Composite Using Ti-28Ni Eutectic Brazing Alloy, Int. J. Refract. Met. Hard Mater., 2017, 69, p 240–246

X.R. Song, H.J. Li, X. Zeng, and L. Zhang, Brazing of C/C Composites to Ti6Al4V Using Graphene Nanoplatelets Reinforced TiCuZrNi Brazing Alloy, Mater. Lett., 2016, 183, p 232–235. https://doi.org/10.1016/j.matlet.2016.07.111

X.R. Song, H.J. Li, and X. Zeng, Brazing of C/C Composites to Ti6Al4V Using Multiwall Carbon Nanotubes Reinforced TiCuZrNi Brazing Alloy, J. Alloys Compd., 2016, 664, p 175–180

Z.W. Yang, L.X. Zhang, P. He, and J.C. Feng, Interfacial Structure and Fracture Behavior of TiB Whisker-Reinforced C/SiC Composite and TiAl Joints Brazed with Ti-Ni-B Brazing Alloy, Mater. Sci. Eng., A, 2012, 532, p 471–475

Z. Doni, A.C. Alves, F. Toptan, J.R. Gomes, A. Ramalho, M. Buciumeanu, L. Palaghian, and F.S. Silva, Dry Sliding and Tribocorrosion Behaviour of Hot Pressed CoCrMo Biomedical Alloy as Compared with the Cast CoCrMo and Ti6Al4V Alloys, Mater. Des., 2013, 52, p 47–57

M. Rafiei, M. Salehi, and M. Shamanian, Formation Mechanism of B4C-TiB2-TiC Ceramic Composite Produced by Mechanical Alloying of Ti-B4C Powders, Adv. Powder Technol., 2014, 25(6), p 1754–1760

M. Frary, S. Abkowitz, S.M. Abkowitz, and D.C. Dunand, Microstructure and Mechanical Properties of Ti/W and Ti-6Al-4V/W Composites Fabricated by Powder-Metallurgy, Mater. Sci. Eng., A, 2003, 344(1–2), p 103–112

B.T.M.T. Godfrey, P.S. Goodwin, and C.M. Ward-close, Titanium Particulate Metal Matrix Composites, Adv. Eng. Mater., 2000, 4(3), p 85–92

P. Villars, A. Prince, and H. Okamoto, Eds., Handbook of Ternary Alloy Phase Diagrams, ASM International, Materials Park, OH, 1995

S.J. Lee, S.K. Wu, and R.Y. Lin, Infrared Joining of TiAl Intermetallics Using Ti-15Cu-15Ni Foil—I. The Microstructure Morphologies of Joint Interface, Acta Mater., 1998, 46(4), p 1283–1295

L. Gomes and A. Guedes, Influence of the Brazing Filler on the Microstructure of Ti6Al4V Joints, Microsc. Microanal., 2016, 22(S4), p 40–41

V.G. Pina, V. Amigó, and A.I. Muñoz, Microstructural, Electrochemical and Tribo-electrochemical Characterisation of Titanium-Copper Biomedical Alloys, Corros. Sci., 2016, 109, p 115–125

J.M. Shi, L.X. Zhang, Q. Chang, Z. Sun, and J.C. Feng, Strengthening the ZrC-SiC Ceramic and TC4 Alloy Brazed Joint Using Laser Additive Manufactured Functionally Graded Material Layers, Ceram. Int., 2018, 44(10), p 11060–11069

X.-G. Song, T. Zhang, Y.-J. Feng, C.-W. Tan, J. Cao, and W.-C. Zhang, Brazing of TiBw/TC4 Composite and Ti60 Alloy Using TiZrNiCu Amorphous Filler Alloy, Trans. Nonferrous Met. Soc. China, 2017, 27(10), p 2193–2201

J.C. Schuster and G. Cacciamani, Cu-Ni-Ti (Copper-Nickel-Titanium), Light Metals Systems. Part 4, G. Effenber and S. Ilyenko, Ed., Springer, New York, 2006, p 266–283

F. Toptan, A.C. Alves, M.A. Ferreira, C.I. da Silva Oliveira, and A.M.P. Pinto, Effect of HAP Decomposition on the Corrosion Behavior of Ti-HAP Biocomposites, Mater. Corros., 2018, 69(9), p 1292–1299

F. Toptan, A. Rego, A.C. Alves, and A. Guedes, Corrosion and Tribocorrosion Behavior of Ti-B4C Composite Intended for Orthopaedic Implants, J. Mech. Behav. Biomed. Mater., 2016, 61, p 152–163

A.M. Ribeiro, A.C. Alves, F.S. Silva, and F. Toptan, Electrochemical Characterization of Hot Pressed CoCrMo-HAP Biocomposite in a Physiological Solution, Mater. Corros., 2015, 66(8), p 790–795

S.C. Ferreira, L.A. Rocha, E. Ariza, P.D. Sequeira, Y. Watanabe, and J.C.S. Fernandes, Corrosion Behaviour of Al/Al3Ti and Al/Al3Zr Functionally Graded Materials Produced by Centrifugal Solid-Particle Method: Influence of the Intermetallics Volume Fraction, Corros. Sci., 2011, 53(6), p 2058–2065. https://doi.org/10.1016/j.corsci.2011.02.010

E. Zhang, S. Li, J. Ren, L. Zhang, and Y. Han, Effect of Extrusion Processing on the Microstructure, Mechanical Properties, Biocorrosion Properties and Antibacterial Properties of Ti-Cu Sintered Alloys, Mater. Sci. Eng. C, 2016, 69, p 760–768. https://doi.org/10.1016/j.msec.2016.07.051

R. Zhang, H. Wang, X. Xing, Z. Yuan, S. Yang, Z. Han, and G. Yuan, Effects of Ni Addition on Tribocorrosion Property of TiCu Alloy, Tribol. Int., 2017, 107, p 39–47. https://doi.org/10.1016/j.triboint.2016.11.010

Acknowledgments

This work is supported by FCT with the reference project UID/EEA/04436/2019, M-ERA-NET/0001/2015, and Proc.º 4.4.1.00 FCT/CAPES projects.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sousa, J.M., Alves, A.C., Toptan, F. et al. Corrosion and Tribocorrosion Behavior of Ti-B4C Composites Joined with TiCuNi Brazing Alloy. J. of Materi Eng and Perform 28, 4972–4982 (2019). https://doi.org/10.1007/s11665-019-04217-6

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-019-04217-6