Abstract

The reduction of the fish oil acidity is a significant problem in the rendering industry, as the oil’s range of applications and market value strongly depend on this parameter. In particular, the lower the acidity, the larger the oil’s market value. This work aims to study the potential of enzymatic esterification for reducing the fish oil acidity, by converting the free fatty acids into esters. Thus, four commercial lipases were used and a parametric study was performed to identify the best operating conditions, varying the reaction temperature, enzyme/oil mass ratio and alcohol/FFA mass ratio. All experiments were performed in duplicate with a very good reproducibility of results. Results showed that Lipozyme TL 100L contributed to greater acidity reduction (75% from an initial acid value of 10–14 mg KOH/g oil) for esterification at 40 °C, using ethanol 96% v/v, enzyme/oil and alcohol/FFA mass ratios of 0.01 and 3.24 w/w, respectively, reaching 3.13 mg KOH/g oil of final acid value or 1.57% FFA content. The reaction kinetics were also studied and it was found that a second order rate law as a function of the alcohol and oil concentrations is more adequate, with 35.44 kJ/mol of activation energy and 1.94 × 103 L mol− 1 min− 1 of pre-exponential factor. In conclusion, this work shows that the enzymatic esterification to reduce the fish oil acidity is technically feasible, increasing its market value.

Similar content being viewed by others

References

Seafish: Fishmeal and fish oil facts and figures. Sea Fish Industry Authority, UK, December http://www.seafish.org/media/publications/SeafishFishmealandFishOilFactsandFigures_201612.pdf (2016)

Pike, I.H., Jackson, A.: Fish oil: production and use now and in the future. Lipid Technol. 22(3), 59–61 (2010)

Mata, T.M., Correia, D., Pinto, A., Andrade, S., Trovisco, I., Matos, E., Martins, A.A., Caetano, N.S.: Fish oil acidity reduction by enzymatic esterification. Energy Procedia 136, 474–480 (2017)

Mata, T.M., Pinto, F., Caetano, N., Martins, A.A.: Economic and environmental analysis of animal fats acidity reduction by enzymatic esterification. J. Cleaner Prod. 184, 481–489 (2018)

Mata, T.M., Trovisco, I., Pinto, A., Matos, E., Martins, A.A., Caetano, N.S.: Enzymatic esterification for acidity reduction of poultry fat. Chem. Eng. Trans. 57, 2005–2010 (2017). https://doi.org/10.3303/CET1757335

Mata, T.M., Andrade, S., Correia, D., Matos, E., Martins, A.A., Caetano, N.S.: Acidity reduction of mammalian fat by enzymatic esterification. Energy Procedia 136, 290–295 (2017)

Mata, T.M., Mendes, A.M., Caetano, N.S., Martins, A.A.: Properties and sustainability of biodiesel from animal fats and fish oil. Chem. Eng. Trans. 38, 175–180 (2014) https://doi.org/10.3303/CET1438030

Mata, T.M., Martins, A.A., Caetano, N.S.: Valorization of waste frying oils and animal fats for biodiesel production. In: Lee, J. (ed.) Advanced Biofuels and Bioproducts, pp. 671–693. Springer, New York (2013)

Caetano, N.S., Mata, T.M., Martins, A.A., Felgueiras, M.C.: New trends in energy production and utilization Energy Procedia 107, 7–14 (2017)

Mata, T.M., Martins, A.A., Caetano, N.S.: Bio-refinery approach for spent coffee grounds valorization. Biores. Technol. 247, 1077–1084 (2018)

Martins, A.A., Pinto, F., Caetano, N.S., Mata, T.M.: Acidity reduction in animal fats by enzymatic esterification: economic and environmental analysis. Energy Procedia 136, 308–315 (2017)

Vilela, L., Mata, T.M., Caetano, N.S.: Biodiesel production from fish oil with high acidity. In: Third International Symposium on Energy from Biomass and Waste (Venice 2010), Venice-Italy, Session C09, Paper 322, 8–11 November (2010)

Caetano, N.S., Silva, V.F.M., Melo, A.C., Martins, A.A., Mata, T.M.: Spent coffee grounds for biodiesel production and other applications. Clean Technol. Environ. Policy 16(7), 1423–1430 (2014)

Ghosh, S., Bhattacharyya, D.K.: Utilization of acid oils in making valuable fatty products by microbial lipase technology. J. Am. Oil Chem. Soc. 72, 1541–1544 (1995)

Caetano, N.S., Teixeira, J.M.I., Mata, T.M.: Enzymatic catalysis of vegetable oil with ethanol in the presence of co-solvents. Chem. Eng. Trans. 26, 81–166 (2012) https://doi.org/10.3303/CET1226014

Caetano, N.S., Caldeira, D., Martins, A.A., Mata, T.M.: Valorization of spent coffee grounds: production of biodiesel via enzymatic catalysis with ethanol and a co-solvent. Waste Biomass Valorization 8(6), 1981–1984 (2017)

Mata, T.M., Sousa, I.R.B.G., Caetano, N.S.: Transgenic corn oil for biodiesel production via enzymatic catalysis with ethanol. Chem. Eng. Trans. 27, 19–24 (2012). https://doi.org/10.3303/CET1227004

Miller, C., Austin, H., Posorske, L., Gonzlez, J.: Characteristics of an immobilized lipase for the commercial synthesis of esters. J. Am. Oil Chem. Soc. 65, 927–931 (1988)

Mata, T.M., Sousa, I.R.B.G., Vieira, S.S., Caetano, N.S.: Biodiesel production from corn oil via enzymatic catalysis with ethanol. Energy Fuels 26(5), 3034–3041 (2012)

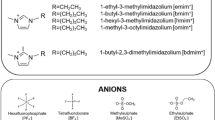

Ruzich, N.I., Bassi, A.S.: Investigation of enzymatic biodiesel production using ionic liquid as a co-solvent. Can. J. Chem. Eng. 88(2), 277–282 (2010)

Facioli, N.L., Barrera-Arellano, D.: Optimisation of enzymatic esterification of soybean oil deodoriser distillate. J. Sci. Food Agric. 81(12), 1193–1198 (2001)

Haas, M.J., Scott, K.M.: Combined nonenzymatic-enzymatic method for the synthesis of simple alkyl fatty acid esters from soapstock. J. Am. Oil Chem. Soc. 73(11), 1393–1401 (1996)

Hajamini, Z., Sobati, M.A., Shahhosseini, S., Ghobadian, B.: Waste fish oil (WFO) esterification catalyzed by sulfonated activated carbon under ultrasound irradiation. Appl. Therm. Eng. 94, 141–150 (2016)

Mittelbach, M.: Lipase-catalyzed alcoholysis of sunflower oil. J. Am. Oil Chem. Soc. 67, 168–170 (1990)

Linko, Y.-Y., Lamsa, M., Huhtala, A., Rantanen, O.: Lipase biocatalysis in the production of esters. J. Am. Oil Chem. Soc. 72, 1293–1299 (1995)

Ghoshray, S., Bhattacharyya, D.K.: Enzymatic preparation of ricinoleic acid esters of long-chain monohydric alcohols and properties of the esters. J. Am. Oil Chem. Soc. 69, 85–88 (1992)

Hirata, H., Higuchi, K., Yamashina, T.: Lipase-catalyzed transesterification in organic solvent: effects of water and solvent, thermal stability and some applications. J. Biotechnol. 14(2), 157–167 (1990)

Gandhi, N.N., Patil, N.S., Sawant, S.B., Joshi, J.J.B., Wangikar, P.P., Mukesh, D.: Lipase-catalyzed esterification. Catal. Rev. 42(4), 439–480 (2000)

Valivety, R.H., Halling, P.J., Macrae, A.R.: Water as a competitive inhibitor of lipase-catalysed esterification in organic media. Biotechnol. Lett. 15(11), 1133–1138 (1993)

Sun, J., Liu, S.-Q.: Ester synthesis in aqueous media by lipase: alcoholysis, esterification and substrate hydrophobicity. J. Food Biochem. 39(1), 11–18 (2015)

Svensson, I., Wehtje, E., Adlercreutz, P., Mattiasson, B.: Effects of water activity on reaction rates and equilibrium positions in enzymatic esterifications. Biotechnol. Bioeng. 44(5), 549–556 (1994)

Bloomer, S., Adlercreutz, P., Mattiasson, B.: Facile synthesis of fatty acid esters in high yields. Enzyme Microb. Technol. 14(7), 546–552 (1992)

ISO 12966-2: Animal and Vegetable Fats and Oils—Gas Chromatography of Fatty Acid Methyl Esters—Part 2. International Organization for Standardization, Geneva (2011)

Santos, L.A.T., Cruz, R., Casal, S.: Trans fatty acids in commercial cookies and biscuits: an update of Portuguese market. Food Control 47, 141–146 (2015)

ISO 18395: Animal and Vegetable Fats and Oils—Determination of Monoacylglycerols, Diacylglycerols, Triacylglycerols and Glycerol by High-Performance Size-Exclusion Chromatography (HPSEC). International Organization for Standardization, Geneva (2005)

ISO 3596: Animal and Vegetable Fats and Oils—Determination of Unsaponifiable Matter—Method Using Diethyl Ether Extraction. International Organization for Standardization, Geneva (2000)

Levenspiel, O.: Chemical Reaction Engineering, 3rd edn., Wiley, Hoboken (1999)

Masson, L., Alfaro, T., Camilo, C., Carvalho, A., Illesca, P., Torres, R., Tavares do Carmo, M., Mancini-Filho, J., Bernal, C.: Fatty acid composition of soybean/sunflower mix oil, fish oil and butterfat applying the AOCS Ce 1j-07 method with a modified temperature program. Grasas Aceites 66(1), e064 (2015)

Minarny, G., Purnomo, H., Rosyidi, D.: Fatty acid profile of fish from Central Sulawesi, Indonesia. Int. Food Res. J. 21(3), 943–947 (2014)

Romero, N., Robert, P., Masson, L., Luck, C., Buchmann, L.: Composition in fatty acid and contribution of cholesterol of mackerel, sardine, salmon and tuna in natural fish canned. Arch. Latinoam. Nutr. 46, 75–77 (1996)

Rani, K.N.P., Neeharika, T.S.V.R., Kumar, T.P., Satyavathi, B., Sailu, Ch, Prasad, R.B.N.: Kinetics of enzymatic esterification of oleic acid and decanol for wax ester and evaluation of its physico-chemical properties. J. Taiwan Inst. Chem. Eng. 55, 12–16 (2015)

Radzi, S.M., Mohamad, R., Basri, M., Salleh, A.B., Ariff, A., Rahman, M.B.A., Rahman, R.N.Z.R.A.: Kinetics of enzymatic synthesis of liquid wax ester from oleic acid and oleyl alcohol. J. Oleo Sci. 59, 127–134 (2010)

Mahmud, M.S., Safinski, T., Nelson, M.I., Sidhu, H.S., Adesina, A.A.: Kinetic analysis of oleic acid esterification using lipase as catalyst in a microaqueous environment. Ind. Eng. Chem. Res. 49(3), 1071–1078 (2010)

Acknowledgements

Authors would like to thank Novozymes for their kind offer of enzymes used in this work. Authors thank the financial support of projects PP-IJUP2014-SOJA DE PORTUGAL funded by Soja de Portugal SGPS SA and POCI-01-0145-FEDER-006939 (Laboratory for Process Engineering, Environment, Biotechnology and Energy—LEPABE) funded by FEDER through COMPETE2020—POCI and by national funds through FCT. Authors also thank FCT for project FCT UID/EQU/00305/2013 (Center for Innovation in Engineering and Industrial Technology—CIETI) and for their support through provision of the research Grants IF/01093/2014 and SFRH/BPD/112003/2015.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mata, T.M., Correia, D., Andrade, S. et al. Fish Oil Enzymatic Esterification for Acidity Reduction. Waste Biomass Valor 11, 1131–1141 (2020). https://doi.org/10.1007/s12649-018-0357-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-018-0357-z