Abstract

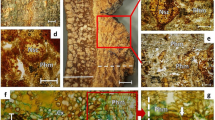

Pine nut industry residues, scales and core from pinecones and shells from the nuts from Pinus pinea were fully characterized. The anatomical sections showed differences between the residues. The scales presented vascular bundles with thick tracheids and narrow lumens in the xylem. The core structure presents xylem, phloem, and sclerenchyma tissues, mainly sclereids with polylamellated walls with different wall thicknesses, shapes and sizes. Nutshells presented a thickened epidermis followed by a large portion of sclereids. The chemical composition of scales and core were similar. Scales presented 0.8% ash content, 5.7% total extractives, 35.8% total lignin, and 56.8% in polysaccharides. Core showed slightly lower cell lignification (31.6% of total lignin) and higher monosaccharides content (60.1%), with 5.5% and 1.7% extractives and ashes. Nutshells had a higher lignin content (49.5%), lower content of monosaccharides (41.8%) and similar values of extractives (6.0%) and ash (1.6%). Lignin monomeric composition was similar, with a H/G ratio of 0.066 (scales), 0.039 (core) and 0.070 (nutshells). The ethanolic extracts presented low to moderate antioxidant activities in FRAP and DPPH methods. Thermal properties of the three residues were very similar; on average, the residues presented 77.1% of total volatiles, 21.9% of fixed carbon and 0.9% of ashes.

Graphical Abstract

Similar content being viewed by others

Data availability

All data generated or used during this study are present in this article.

References

IFN6. 6º Inventário Florestal Nacional. https://www.icnf.pt/api/file/doc/c8cc40b3b7ec8541 (2015), Accessed 25th May 2022.

Evaristo, I., Batista, D., Correia, I., Correia, P., Costa, R.: Chemical profiling of Portuguese Pinus pinea L. nuts. J. Sci. Food Agric. 90, 1041–1049 (2010). https://doi.org/10.1002/jsfa.3914

Losada, J.M., Blanco-Moure, N., Leslie, A.B.: Not all ‘pine cones’ flex: functional trade-offs and the evolution of seed release mechanisms. New Phytol. 222, 396–407 (2019). https://doi.org/10.1111/nph.15563

Bae, H., Kim, J.: Functional principles of morphological and anatomical structures in pinecones. Plants. 9, 1343 (2020). https://doi.org/10.3390/plants9101343

Correa, D., Poppinga, S., Mylo, M.D., Westermeier, A.S., Bruchmann, B., Menges, A., Speck, T.: 4D pine scale: biomimetic 4D printed autonomous scale and flap structures capable of multi-phase movement. Philos. Trans. R Soc. A Math. Phys. Eng. Sci. 378, 20190445 (2020). https://doi.org/10.1098/rsta.2019.0445

Queirós, C.S.G.P., Cardoso, S., Lourenço, A., Ferreira, J., Miranda, I., Lourenço, M.J.V., Pereira, H.: Characterization of walnut, almond, and pine nut shells regarding chemical composition and extract composition. Biomass Convers. Biorefinery. 10, 175–188 (2020). https://doi.org/10.1007/s13399-019-00424-2

Dönmez, I.E., Hafizoğlu, H., Killic, A., Tümen, I., Sivrikaya, H.: Chemical composition of fourteen different coniferous species cones growing naturally in Turkey. Wood Res. 57(2), 339–344 (2012)

Gonultas, O., Balaban Ucar, M.: Characteristics of pinus. Lignocellulose 2, 262–269 (2013)

Ayrilmis, N., Buyuksari, U., Avci, E., Koc, E.: Utilization of pine (Pinus pinea L.) cone in manufacture of wood based composite. For. Ecol. Manag. 259, 65–70 (2009). https://doi.org/10.1016/j.foreco.2009.09.043

Buyuksari, U., Ayrilmis, N., Avci, E., Koc, E.: Evaluation of the physical, mechanical properties and formaldehyde emission of particleboard manufactured from waste stone pine (Pinus pinea L.) cones. Bioresour. Technol. 101, 255–259 (2010). https://doi.org/10.1016/j.biortech.2009.08.038

García-García, D., Balart, R., Lopez-Martinez, J., Ek, M., Moriana, R.: Optimizing the yield and physico-chemical properties of pine cone cellulose nanocrystals by different hydrolysis time. Cellulose 25, 2925–2938 (2018). https://doi.org/10.1007/S10570-018-1760-0/FIGURES/5

Ucun, H., Bayhan, Y.K., Kaya, Y., Cakici, A., Faruk Algur, O.: Biosorption of chromium(VI) from aqueous solution by cone biomass of Pinus sylvestris. Bioresour. Technol. 85, 155–158 (2002). https://doi.org/10.1016/S0960-8524(02)00086-X

Koubaissy, B., Toufaily, J., Cheikh, S., Hassan, M.S., Hamieh, T.: Valorization of agricultural waste into activated carbons and its adsorption characteristics for heavy metals. Cent. Eur. J. Eng. 4, 90–99 (2014). https://doi.org/10.2478/s13531-013-0148-z

Gulsoy, S.K., Ozturk, F.: Kraft pulping properties of European black pine cone. Maderas Cienc y Tecnol. (2015). https://doi.org/10.4067/S0718-221X2015005000076

Naushad, M., Ali Khan, M., Abdullah Alothman, Z., Rizwan Khan, M., Kumar, M.: Adsorption of methylene blue on chemically modified pine nut shells in single and binary systems: isotherms, kinetics, and thermodynamic studies. Desalin. Water Treat. 57, 15848–15861 (2016). https://doi.org/10.1080/19443994.2015.1074121

Uçar, S., Karagöz, S.: Co-pyrolysis of pine nut shells with scrap tires. Fuel 137, 85–93 (2014). https://doi.org/10.1016/j.fuel.2014.07.082

Barbosa, A.C.F., Pace, M.R., Witovisk, L., Angyalossy, V.: A new method to obtain good anatomical slides of heterogeneous plant parts. IAWA J. 31, 373–383 (2010). https://doi.org/10.1163/22941932-90000030

Miranda, I., Lima, L., Quilhó, T., Knapic, S., Pereira, H.: The bark of Eucalyptus sideroxylon as a source of phenolic extracts with anti-oxidant properties. Ind. Crops Prod. 82, 81–87 (2016). https://doi.org/10.1016/j.indcrop.2015.12.003

Ferreira, J.P.A., Miranda, I., Gominho, J., Pereira, H.: Selective fractioning of Pseudotsuga menziesii bark and chemical characterization in view of an integrated valorization. Ind. Crops Prod. 74, 998–1007 (2015). https://doi.org/10.1016/j.indcrop.2015.05.065

Scherer, R., Godoy, H.T.: Antioxidant activity index (AAI) by the 2,2-diphenyl-1-picrylhydrazyl method. Food Chem. 112, 654–658 (2009). https://doi.org/10.1016/j.foodchem.2008.06.026

Faix, O., Meier, D., Fortmann, I.: Thermal degradation products of wood. Holz als Roh- und Werkst. 48, 281–285 (1990). https://doi.org/10.1007/BF02626519

Ralph, J., Hatfield, R.D.: Pyrolysis-GC-MS characterization of forage materials. J. Agric. Food Chem. 39, 1426–1437 (1991). https://doi.org/10.1021/jf00008a014

Le Duigou, A., Castro, M.: Evaluation of force generation mechanisms in natural, passive hydraulic actuators. Sci. Rep. 6, 18105 (2016). https://doi.org/10.1038/srep18105

Pereira, H., Graca, J., Rodrigues, J.C.: Wood Chemistry in Relation to Quality. ChemInform (2004). https://doi.org/10.1002/CHIN.200446298

Nergiz, C., Dönmez, I.: Chemical composition and nutritive value of Pinus pinea L. seeds. Food Chem. 86, 365–368 (2004). https://doi.org/10.1016/j.foodchem.2003.09.009

Lourenço, A., Pereira, H.: Compositional variability of lignin in biomass. Lignin—Trends Appl. (2018). https://doi.org/10.5772/INTECHOPEN.71208

Lourenço, A., Gominho, J., Pereira, H.: Chemical characterization of lignocellulosic materials by analytical pyrolysis. Anal. Pyrolysis. (2018). https://doi.org/10.5772/INTECHOPEN.80556

Eberhardt, T.L., Young, R.A.: Characterization of conifer seed cone polysaccharides and lignin. Holzforschung 50, 401–407 (1996). https://doi.org/10.1515/hfsg.1996.50.5.401

Sousa, J.L.C., Ramos, P.A.B., Freire, C.S.R., Silva, A.M.S., Silvestre, A.J.D.: Chemical composition of lipophilic bark extracts from Pinus pinaster and Pinus pinea cultivated in Portugal. Appl. Sci. 8, 2575 (2018). https://doi.org/10.3390/app8122575

Lazar, L., Talmaciu, A.I., Volf, I., Popa, V.I.: Kinetic modeling of the ultrasound-assisted extraction of polyphenols from Picea abies bark. Ultrason. Sonochem. 32, 191–197 (2016). https://doi.org/10.1016/j.ultsonch.2016.03.009

Zulaica-Villagomez, H., Peterson, D.M., Herrin, L., Young, R.A.: Antioxidant activity of different components of pine species. Holzforschung 59, 156–162 (2005). https://doi.org/10.1515/HF.2005.024

White, R.: Effect of lignin content and extractives on the higher heating value of wood. Wood Fiber Sci. 19, 446–452 (1987)

Rowell, R.M.: Handbook of Wood Chemistry and Wood Composites. CRC Press, Boca Raton (2005). https://doi.org/10.1201/9780203492437

Pandey, K.K.: A study of chemical structure of soft and hardwood and wood polymers by FTIR spectroscopy. J. Appl. Polym. Sci. 71, 1969–1975 (1999). https://doi.org/10.1002/(SICI)1097-4628(19990321)71:12%3c1969::AID-APP6%3e3.0.CO;2-D

Schwanninger, M., Rodrigues, J.C., Pereira, H., Hinterstoisser, B.: Effects of short-time vibratory ball milling on the shape of FT-IR spectra of wood and cellulose. Vib. Spectrosc. 36, 23–40 (2004). https://doi.org/10.1016/j.vibspec.2004.02.003

ENplus ® Standard ENplus ® wood pellets-requirements for companies. https://www.enplus-pellets.eu/en-in/component/attachments/?task=download&id=697:ENplus-ST-1001---ENplus-wood-pellets--Requirements-for-companies (2022), Accessed 12 Jan 2023.

Lee, T.K., Roh, H.S., Yu, J.S., Baek, J., Lee, S., Ra, M., Kim, S.Y., Baek, K.H., Kim, K.H.: Pinecone of Pinus koraiensis inducing apoptosis in human lung cancer cells by activating caspase-3 and its chemical constituents. Chem. Biodivers. (2017). https://doi.org/10.1002/CBDV.201600412

Yi, J., Qu, H., Wu, Y., Wang, Z., Wang, L.: Study on antitumor, antioxidant and immunoregulatory activities of the purified polyphenols from pinecone of Pinus koraiensis on tumor-bearing S180 mice in vivo. Int. J. Biol. Macromol. 94, 735–744 (2017). https://doi.org/10.1016/J.IJBIOMAC.2016.10.071

Yi, J., Wang, Z., Bai, H., Yu, X., Jing, J., Zuo, L.: Optimization of purification, identification and evaluation of the in vitro antitumor activity of polyphenols from Pinus koraiensis pinecones. Molecules 20, 10450–10467 (2015). https://doi.org/10.3390/MOLECULES200610450

Bhatia, L., Sharma, A., Bachheti, R.K., Chandel, A.K.: Lignocellulose derived functional oligosaccharides: production, properties, and health benefits. Prep. Biochem. Biotechnol. 49, 744–758 (2019). https://doi.org/10.1080/10826068.2019.1608446

Acknowledgements

The authors thank Miguel Figueiredo and PineFlavour for providing the Pinus pinea residues used in this study and Marta Martins for the thermogravimetric data acquisition. This work was supported by FCT (Fundação para a Ciência e Tecnologia, Portugal) by financing the Forest Research Center (UIDB/00239/2020 and UIDP/00239/2021). FCT supported Ana Lourenço through a research contract (DL 57/2016/CP1382/CT0007) and Ricardo Costa through a doctoral fellowship with reference 2020.07451.BD.

Funding

This study was supported by Fundação para a Ciência e a Tecnologia (Grant Nos. UIDB/00239/2020, UIDP/00239/2021, DL 57/2016/CP1382/CT0007, 2020.07451.BD).

Author information

Authors and Affiliations

Contributions

RAC—Conceptualization, Methodology, Investigation, Data analysis, Writing—original draft, Writing—review and editing. AL—Conceptualization, Data analysis, Writing—review and editing, Funding acquisition, Supervision. HP—Methodology, Writing—review and editing. TQ—Methodology, Writing—review and editing. JG—Conceptualization, Data analysis, Writing—review and editing, Resources, Supervision, Funding acquisition.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing financial interests or personal relationships that could have any influence in this work.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Costa, R.A., Lourenço, A., Patrício, H. et al. Valorization of Pine Nut Industry Residues on a Biorefinery Concept. Waste Biomass Valor 14, 4081–4099 (2023). https://doi.org/10.1007/s12649-023-02068-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-023-02068-w