Abstract

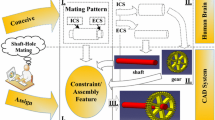

A large number of decisions are made during the conceptual design stage which is characterized by a lack of complete geometric information. While existing CAD systems supporting the geometric aspects of design have had little impact at the conceptual design stage. To support the conceptual die design and the top–down design process, a new concept called conceptual assembly modeling framework (CAMF) is presented in this paper. Firstly, the framework employs the zigzag function-symbol mapping to implement the function design of the die. From the easily understood analytical results of the function-symbol mapping matrix, the designer can evaluate the quality of a proposed die concept. Secondly, a new method—logic assembly modeling is proposed using logic components in this framework to satisfy the characteristic of the conceptual die design. Representing shapes and spatial relations in logic can provide a natural, intuitive method of developing complete computer systems for reasoning about die construction design at the conceptual stage. The logic assembly which consists of logic components is an innovative representation that provides a natural link between the function design of the die and the detailed geometric design.

Similar content being viewed by others

References

Albano, L. D. and Suh, N. P. (1994) Axiomatic design and concurrent engineering. Computer-Aided Design, 26, 499-504.

Dodhi, R. and Turner, J. U. (1994) Towards modelling of assemblies for product design. Computer-Aided Design, 26, 85-97.

Gorti, S. R. and Sriram, R. D. (1996) From symbol to form: a framework for conceptual design. Computer-Aided Design, 28, 853-870.

Gorti, S. R., Gupta, A., Kim, G. J., Sriram, R. D. and Wong, A. (1998) An object-oriented representation for product and design processes. Computer-Aided Design, 30, 489-501.

Gui, J. K. and Mantyla, M. (1994) Functional understanding of assembly modelling. Computer-Aided Design, 26, 435-451.

Harutunian, V., Nordlund, M., Tate, D. and Suh, N. P. (1996) Decision making and software tools for product development based on axiomatic design theory. Annals of CIRP, 45, 135-139.

Iwata, K. and Onosato, M. (1989) A computer aided conceptual design system of machine. Annals of CIRP, 38, 137-140.

Jiang, X., Yang, R., Zhang, Z. and He, Y. (1997) A research on the mapping between function and structure in CAD. v J. CAD&CG, 9, 442-448 (in Chinese).

Kim, S. J. and Suh, N. P. (1991) Design of software system based on axiomatic design. Annals of CIRP, 40, 165-170.

Kim, C. and O'Grady, P. J. (1996) A representation formalism for feature-based design. Computer-Aided Design, 28, 451-459.

Lee, K. and Gossard, D. C. (1985) A hierarchical data structure for representing assemblies: Part 1. Computer-Aided Design, 17, 15-24.

Lyons, K., Shooter, S., Keirouz, W. and Hart, P. The open assembly design environment project: an architecture for design agent interoperability. http://www.nist.gov/ msidlibrary/pubs.html.

Mantyla, M. (1990) A modelling system for top-down design of assembled products. IBM J. Res. Develop, 34, 636-644.

Mukherjee, A. and Liu, C. R. (1997) Conceptual design, manufacturability and process planning using functionform relationships in stamped metal parts. Robotics & Computer-Integrated Manufacturing, 13, 253-270.

Ranta, M., Mantyla, M., Umeda, Y. and Tomiyama, T. (1996) Integration of functional and feature-based product modelling: the IMS/GNOSIS experience. Computer-Aided Design, 28, 371-381.

Wood, W. H. III and Agogino, A. M. (1996) Cased-based conceptual design information sever for concurrent engineering. Computer-Aided Design, 28, 361-369.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Tang, DB., Li, D. & Zhang, S. A conceptual approach for the die structure design. Journal of Intelligent Manufacturing 12, 43–56 (2001). https://doi.org/10.1023/A:1008951529971

Issue Date:

DOI: https://doi.org/10.1023/A:1008951529971