Abstract

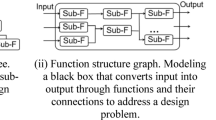

Quality function deployment (QFD) is a cross-functional planning tool that ensures that the voice of the customer is systematically deployed throughout the product planning and design stages. Although many success applications of QFD have been reported worldwide, designers face impediments to the adoption of QFD as a product design aid. One of the difficulties associated with the application of QFD is the large size of a house of quality (HOQ) chart, which is the principal tool for QFD. It is well-known that it becomes more difficult and inefficient to manage a design project as the problem size becomes larger. This paper proposes to develop formal approaches to reducing the size of an HOQ chart using the concept of design decomposition. The decomposition approaches developed attempt to partition an HOQ chart into several smaller sub-HOQ charts which can be solved efficiently and independently. By decomposing a large HOQ chart into smaller sub-HOQ charts, the design team not only can enhance the concurrency of the design activities, but also reduce the amount of the time, effort, and cognitive burden required for the analysis. This would help to obviate the objections to the adoption of QFD as a product design aid and improve the efficiency of its use in practice.

Similar content being viewed by others

References

Adiano, C. and Roth, A. (1993) Beyond the house of quality: Dynamic QFD, IBM Corporation.

Ahn, J. (1996) Letter to author, September 17.

Akao, Y. (1990) Quality Function Deployment: Integrating Customer Requirements into Product Design, Productivity Press, Cambridge, Massachusetts.

Armacost, R., Componation, P., Mullens, M. and Swart, W. (1994) An AHP framework for prioritizing customer requirements in QFD: An industrialized housing application. IIE Transactions, 26(4), 72–79.

ASI (1989/1994) Transactions from the Symposium on Quality Function Deployment, American Supplier Institute/GOAL/QPC.

Bordley, R. (1995) Conversation with author, September 26.

Bosserman, S. (1992) Quality Function Deployment: The Competitive Advantage. Private Trunked Systems Division, Motorola.

DeVries, R. and Barton, M. (1995) Conversation with author, October 12.

Geoffrion, A. M. (1974) Lagrangian relaxation in integer programming. Mathematical Programming Study, 2, 82–114.

Gipprich, J. (1987) QFD Case study-Kelsey Hayes Corporation. Quality Function Deployment: A Collection of Presentations and QFD Case Studies, Section VIII, ASI Inc., Dearborn, Michigan.

Griffin, A. (1992) Evaluating QFD's use in US firms as a process for developing products. Journal of Product Innovation Management, 9, 171–187.

Griffin, A. and Hauser, J. (1992) Voice of the Customer. Report 92–106, Marketing Science Institute, Cambridge, Massachusetts.

Grigoriadis, M. D. and Hsu, T. (1979) RNET: The Rutgers minimum cost network flow subroutine. SIGMAP Bulletin, 17–18.

Hauser, J. R. and Clausing, D. (1988) The house of quality. Harvard Business Review, 66, 63–73.

Hunter, M. and Van Landingham, R. (1994) Listening to the customer using QFD. Quality Progress, 27, 55–59.

Iri, M. (1968) On the synthesis of loop and cutset matrices and the related problems. In RAAG Memories, edited by K. Kondo, 4(A-XIII), 376–410.

ITI (1993) QFD/Capture: Quick Tour Guide, Milford, Ohio.

Jordan, M. (1996) Conversation with author, March 28.

Keeney, R. and Raiffa, H. (1976) Decisions with Multiple Objectives, John Wiley and Sons, New York.

Kennington, J. L. and Helgason, R. V. (1980) Algorithms for Network Programming, Wiley, New York.

Kim, Y. (1997) Conversation with author, July. 31.

Kumar, K., Kusiak, A. and Vannelli, A. (1986) Grouping parts and components in flexible manufacturing system. European Journal of Operational Research, 24, 387–397.

Kusiak, A. (1985) The part families problem in flexible manufacturing problems. Annals of Operations Research, 3, 279–300.

Kusiak, A. and Cheng, C. (1990) A branch-and-bound algorithm for solving the group technology problem. Annals of Operations Research, 26, 415–431.

Kusiak, A. and Chow, W. (1987) An efficient cluster identification algorithm. IEEE Transactions on System, Man, and Cybernetics, SMC-17(4), 696–699.

Kusiak, A. and Park, K. (1990) Concurrent engineering: Decomposition and scheduling of design activities. International Journal of Production Research, 28(10), 1883–1900.

Kusiak, A. and Wang, J. (1993) Decomposition of the design process. Journal of Mechanical Design, 115, 687–695.

Liner, M. (1994) QFD comes to Raychem Corporation: The study of a pilot project. In Successful Implementation of Concurrent Engineering Products and Processes, edited by S. G. Sinha, Van Nostrand Reinhold, New York.

McAuley, J. (1972) Machine grouping for efficient production. Production Engineer, 51, 153.

McCormick, W. T., Schweitzer, P. J. and White T. E. (1972) Problem decomposition and data recognition by a clustering technique. Operations Research, 20, 993–1009.

Morrell, N. (1987) Quality case studies-Budd Corporation. Quality Function Deployment: A Collection of Presentations and QFD Case Studies, Section VII, ASI Inc., Dearborn, Michigan.

Moskowitz, H. and Kim, K. (1997) QFD Optimizer: A novice friendly quality function deployment decision support system for optimizing product designs. Computers and Industrial Engineering, 32(3), 641–655.

Mulvey, J. and Crowder, H. (1979) Cluster analysis: An application of Lagrangian relaxation. Management Science, 25, 329–340.

O'Connor, L., Patridge, D., Seely, B., Guthmiller, W. and Lovette, K. (1992) The SeeQFD software: An environment for QFD. SAE International, Worldwide Passenger Car Conference and Exposition, Dearborn, Michigan, September 28-October 1.

Qualisoft Corporation (1991) QFD Designer Manual, West Bloomfield, Michigan.

Shipley, T. (1992) Quality function deployment: Translating customer needs into product specifications. Working Paper, Department of Industrial Engineering and Management Systems, University of Central Florida, Orlando, Florida.

Ventura, J. A., Chen, F. F., and Wu, C. (1990) Grouping parts and tools in flexible manufacturing systems production planning. International Journal of Production Research, 28(6), 1039–1056.

Wu, K. (1996) Decomposition of the house of quality. Master Thesis, The Pennsylvania State University, University Park, Pennsylvania.

Zhang, C. and Wang, H. (1992) Concurrent formation of part families and machine cells based on the fuzzy set theory. Journal of Manufacturing Systems, 11(1), 61–67.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Shin, JS., Kim, KJ. Complexity reduction of a design problem in QFD using decomposition. Journal of Intelligent Manufacturing 11, 339–354 (2000). https://doi.org/10.1023/A:1008970701689

Issue Date:

DOI: https://doi.org/10.1023/A:1008970701689