Abstract

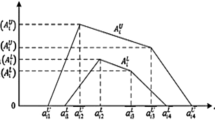

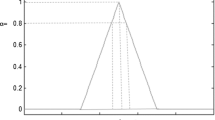

For monitoring multivariate quality control process, traditional multivariate control charts have been proposed to detect mean shifts. However, a persistent problem is that such charts are unable to provide any shift-related information when mean shifts occur in the process. In fact, the immediate classification of the magnitude of mean shifts can greatly narrow down the set of possible assignable causes, hence facilitating quick analysis and corrective action by the technician before many nonconforming units are manufactured. In this paper, we propose a neural-fuzzy model for detecting mean shifts and classifying their magnitude in multivariate process. This model is divided into training and classifying modules. In the training module, a neural network (NN) model is trained to detect various mean shifts for multivariate process. Then, in the classifying module, the outputs of NN are classified into various decision intervals by using a fuzzy classifier and an additional two-point-in-an-interval decision rule to determine shift status. An example is presented to illustrate the application of the proposed model. Simulation results show that it outperforms the multivariate T2control chart in terms of out-of-control average run length under fixed type I error. In addition, the correct classification percentages are also studied and the general guidelines are given for the proper use of the proposed model.

Similar content being viewed by others

References

Chang, S. I. and AW, C. A. (1996) A neural fuzzy control chart for detecting and classifying process shifts. International Journal of Production Research, 34, 2265-2278.

Chang, S. I. and Ho, E. S. (1999) A two-stage network approach for process variance change detection and classification. International Journal of Production Research, 37, 1581-1599.

Cheng, C. S. (1995) A multi-layer neural network model for detecting changes in the process mean. Computers and Industrial Engineering, 28, 51-61.

Crosier, R. B. (1988) Multivariate generalizations of cumulative sum quality control schemes. Technometrics, 30, 291-303.

Guo, Y. and Dooley, K. J. (1992) Identification of change structure in statistical process control. International Journal of Production Research, 30, 1655-1669.

Hirose, Y., Yamashita, K. and Hijiya, S. (1991) Back-propagation algorithm which varies the number of hidden units. Neural Networks, 4, 61-66.

Ho, E. S. and Chang, S. I. (1999) An integrated neural network approach for simultaneous monitoring of process mean and variance shifts—a comparative study. International Journal of Production Research, 37, 1881-1901.

Hotelling, H. (1947) Multivariate quality control-illustrated by the air testing of sample bombsights, in Techniques of Statistical Analysis, McGraw-Hill, New York, pp. 111-184.

Hwarng, H. B. and Hubele, N. F. (1993) X-bar control chart pattern identification through efficient off-line neural network training. IIE Transactions, 25, 27-40.

Jackson, J. E. (1985) Multivariate quality control. Communications in Statistics-Theory and Methods, 14, 2657-2688.

Lowry, C. A. and Woodall, H. W. (1992) A multivariate exponentially weighted moving average control chart. Technometrics, 34, 46-53.

Lowry, C. A. and Montgomery, D. C. (1995) A review of multivariate control charts. IIE Transactions, 27, 800-810.

Mason, R. L., Tracy, N. D. and Young, J. C. (1995) Decomposition of T 2for multivariate control chart interpretation. Journal of Quality Technology, 27, 99-108.

Mason, R. L., Tracy, N. D. and Young, J. C. (1996) Monitoring a multivariate step process. Journal of Quality Technology, 28, 99-108.

Mason, R. L., Tracy, N. D. and Young, J. C. (1997) A practical approach for interpreting multivariate T 2control chart signals. Journal of Quality Technology, 29, 396-406.

Pugh, G. A. (1991) A comparison of neural networks to SPC charts. International Journal of Production Research, 21, 253-255.

Rumelhart, D. E., McClelland, J. L. and the PDP Research Group. (1986) Parallel Distributed Processing: Explorations in the Microstructure of Cognition, MIT Press, Cambridge, MA.

Timm, N. H. (1996) Multivariate quality control using finite intersection tests. Journal of Quality Technology, 28, 233-243.

Zorriassatine, F. and Tannock, J. D. T. (1998) A review of neural networks for statistical process control. Journal of Intelligent Manufacturing, 9, 209-224.

Zurada, J. M. (1992) Introduction to artificial neural systems, PWS Boston.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Wang, TY., Chen, LH. Mean shifts detection and classification in multivariate process: a neural-fuzzy approach. Journal of Intelligent Manufacturing 13, 211–221 (2002). https://doi.org/10.1023/A:1015738906895

Issue Date:

DOI: https://doi.org/10.1023/A:1015738906895